In A Historic First, 2 Chinese Container Ships Cross Paths Just 75 Nautical Miles From The North Pole

MSC Competes with Maersk For Denmark’s Largest Container Port of Aarhus

Watch: Cruise Ship Collides With Large Piece Of Drifting Ice In Alaska

Canadian Coast Guard Acquires Its First-Ever Autonomous Surface Vessel

Bridge of a Ship – Design And Layout

Ships are massive vessels spanning hundreds of meters in length and weighing thousands of tons. Being able to control and manoeuvre such a large vessel is of paramount importance.

How is it possible for a small crew to operate a ship of such gigantic proportions?

This is where the ship’s bridge comes in.

The bridge is the main control centre of a vessel, from where the captain and officers are able to man the entire operations of the vessel . It is generally located in a position with an unrestricted view and immediate access to the essential areas of a ship.

Historically, the bridge was a structure connected to the paddle house that housed the steering equipment . As it closely resembled an actual bridge, this name was given.

Even after paddle wheels became obsolete and were replaced with the latest technological advents, the term “bridge” still stuck. The master of the bridge is always the captain, who retains control and responsibility of the vessel while he is on board.

During the round-the-clock watch, the highest-ranking officer of the watch is generally placed in charge of the bridge. Only authorized personnel are allowed to enter this area and strict operating procedures must be followed at all times.

The bridge of a vessel houses the main steering equipment, navigation charts , communication systems , engine control as well as miscellaneous features. In addition, some bridges also have adjacent bridge wings, that house equipment for the stern and bow thrusters. These wings extend beyond the main bridge room and provide a clear, unobstructed view of the surrounding areas.

The bridge is always manned by an officer of the watch, who has the responsibility of manoeuvring the vessel and coordinating with the engine room. In general, an officer and a lookout are required to be present on the bridge, to prevent any untoward incidents.

For complicated manoeuvres, the captain of the vessel is often called to the bridge to take over controls. And in areas with a high-risk environment, pilots are often enlisted to guide the ship safely using their knowledge of the region. In addition to being the heart of the ship, the bridge is also used as a command centre and important documents are stored here.

The ship’s papers, permits, important documents, passports, cash for emergencies etc. are kept in safe located on the bridge. For this reason, the entrances into the bridge are often heavily fortified and provided with bulletproof glass to thwart pirate attacks .

In this article, we will take a look at the general layout of the bridge, the various components that are found here and the guidelines to be followed.

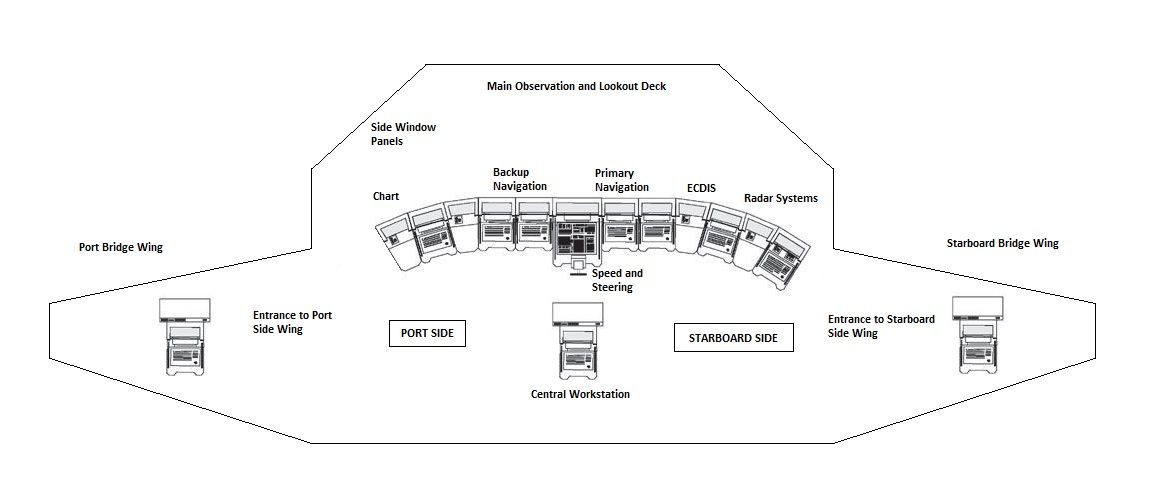

Layout and Design of the Bridge

The bridge of a ship is intended to be the heart of the vessel and must provide a clear and unobstructed view of the surrounding area. Even though a host of electronic and navigational equipment is found on the bridge, the primary purpose must be fulfilled.

Thus, the bridge is demarcated broadly into two regions- the area at the fore intended for clear observation, and the remaining area for controls and comms.

The observation region is enclosed at the fore by large glass panes, built to withstand storms and adverse weather conditions such as hale. Often, plexiglass structures are used and supported on steel or aluminium frames. Shades which can be lowered are also used so that visibility is not reduced when there is a bright light.

Along with the central observation deck, there are also bridge wings. These wings are structures that extend in a transverse manner out of the bridge. Present on the port and starboard side, their primary purpose is to increase the region of visibility, especially during complex manoeuvres such as port docking.

They also house the controls to the individual bow and stern thrusters present on each side. Thrusters are propellers located deep within the hull that provide a higher degree of control to the captain for precise turns and adjustments.

The bridge wings can be either open or closed depending on the type of ship. In most cases, the wings are kept open to allow for maximum visibility. In addition, there is communication equipment found on the wings so that information can be relayed back to the main bridge section. Entry to the bridge wings is restricted to only trained seamen and officers of the watch.

The remaining area of the bridge houses the main navigational, steering and communication equipment. Along with this, there are numerous controls that operate various parts of the ship remotely.

Several internal telephone lines connect the bridge directly to the chief engineer, captain, first officer and the engine room. This enables immediate action based on input from the watch officer.

The control area is built into different console units that are arranged in a semi-circular fashion on all sides of the bridges. This includes radar systems and steering controls that are manned by ship officers.

All equipment used onboard must be IMO certified and must have passed a series of tests intended to check their robust nature and ability to function for protracted periods of time. For safety purposes, fire extinguishers, flares and distress beacons are stored on the bridge.

For anti-piracy reasons, the entire structure is fortified and must pass stringent security checks, especially when sailing through regions such as the Horn of Africa or the Western Indian Ocean region. Although these are hotbeds of criminal activity, most commercial carriers are not allowed to carry firearms or weapons on board.

However, for extreme contingencies, the bridge controls a series of water pumps located all around the ship that thwarts any other vessel from getting too close. Also, special marshals are often hired to provide contracted security and usually keep their firearms on the bridge.

Steering and Engine Equipment on the Bridge

To steer the ship, controls to the rudder , engines and thrusters are present on one of the numerous consoles found in the bridge. Although primary control of the engines rests with the chief engineer or the officer in the engine room, it is an officer from the bridge who often issues commands to the engine room.

To increase speed, there is an engine telegraph that allows for a variety of speeds and even allows the propellers to be put in reverse. There are often different controls for the multiple engines on board. In addition to the engines and propellers, there are bow and stern thrusters that allow for a higher range of precise movements.

The thrusters are often controlled from the bridge wings so that better visibility is available. Thrusters provide steering as their primary function, as compared to power, unlike the engines.

Steering is primarily controlled through the rudder and thrusters, and the controls for both of them rest with the bridge. The rudder must be able to turn to 45⁰ to both the port and starboard side without colliding against the engines. In the case of azipods or integrated propulsion systems, a larger command centre is often used due to the highly sensitive nature of the equipment.

Azipods are an interesting technological invention that allows conventional engines to be integrated with rudders. Thus, a set of azipods are capable of achieving nearly 100% efficiency by turning in almost any direction. This removes the need for different controls for the propulsion and steering systems. In general, controls for the port side are colour-coded red, while the starboard side is often coded green. This allows for easier control by the officers and seamen.

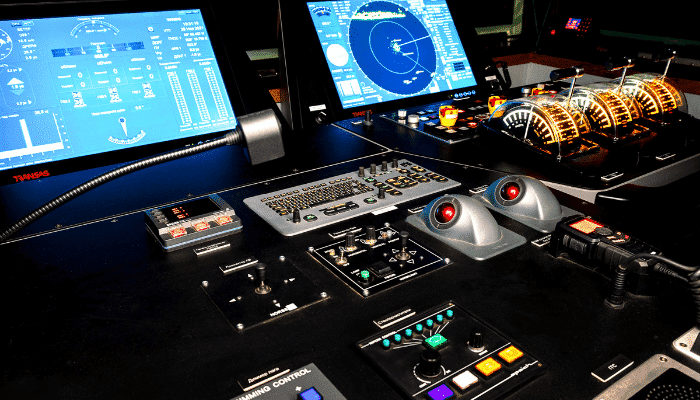

Navigation and Communication on the Bridge

Navigation is a key component of a vessel that is the only means of getting the vessel safely from port to port. Basic navigation equipment includes a Global Positioning System (GPS), Navtex receiver, Electronic Chart Display and Information System (ECDIS), radar systems and communication channels.

Navigation is often controlled using charts that are used to plot routes. To ensure that the vessel stays on course, a combination of GPS and a compass system are used. The charts and equipment are stored in separate locations to ensure the compartmentalization of the bridge. In addition to this, binoculars are used in the daytime for sighting. However, when the weather is not clear, visibility is low or during the night, the radar must be used to accurately place and navigate the ship.

When using radar, a range scale must be used based on the speed and traffic around the vessel. Ships weighing more than 10,000 gross tons must use two radars for potting their course and navigation.

Automatic Radar Plotting Aid (ARPA), Electronic plotting Aids (EPA) and Automatic Tracking Aids (ATA) are also a must on such vessels. Alarms to warn about impending collisions, equipment failure etc. are also used to indicate errors. In certain zones onboard the ship, indicator lights are used to signal warnings.

Bridge Guidelines and Requirements

When at sea, vessels must maintain the strictest of protocols to ensure SOLAS and IMO regulations . As the bridge controls the entire ship, it is essential that the bridge and all equipment satisfy guidelines. For navigation purposes, the bridge must be located with a clear view both ahead and abeam. There must also be a minimum vision of 255⁰ present for the officer on watch (OOW), with at least 112.5⁰ visibility on both the port and starboard sides.

For the bridge wings, the side of the vessel must be clearly visible with 180⁰ on the side and 45⁰ to the opposite side. For the officer in charge of steering, 60⁰ on both sides is the minimum clear visibility.

Ships weighing more than 10,000 gross tonnages must include a single X band – 9 GHz frequency radar. This is according to IMO guidelines for navigation and steering. In case of any contingencies, alarms are positioned at all zones onboard the vessel. These alarms indicate failure of various equipment on the bridge.

In addition, failure or damage from other parts of the ship is also relayed back to the bridge for immediate action. If there is no response from the officer on watch, a backup alarm is signalled after a duration of 30 seconds. This backup alarm is sounded in the offices, mess and cabins indicating a need for assistance.

The Bridge of a Warship

Warships often have a number of bridges that serve multiple purposes. For instance, a navigation bridge houses all navigation-related equipment and charts. It is here that the actual route plotting is completed and relayed to the captain’s bridge. This bridge houses radars that are used for both navigation and military capabilities.

A captain’s bridge is also present, where the captain controls the vessel and the essential components of the warship. When the warship is a central vessel of a fleet or the flagship vessel, it usually has a separate Admirals bridge that is used for strategic and command purposes. Here, the control of the vessel is separated from the control of the vessel. The military staff controlling the fleet are usually housed within this bridge.

Bridge Simulator Systems

The bridge houses extremely sensitive equipment. Being able to successfully sail through a waterbody requires extensive training on the bridge. On average, officers spend years honing their skills before ever being given control of the bridge. In addition, since control over nearly every part of the ship is exercised from the bridge, only trained and authorized personnel are allowed to enter. For training purposes, it is not feasible to give a fresh recruit command over an entire vessel. This is where bridge simulators come into play. They are similar to airplane cockpit simulators but are considerably larger.

Most training institutes have their own simulators that enable recruits to practice on them before actually being deployed onboard a vessel. Several shipping companies also offer specialized simulation software that can be programmed to display a wide range of scenarios.

For instance, MARIN in the Netherlands manufactures and sells various simulation units that project realistic situations to the training officers. A select number of individuals are allowed into the simulator and are allowed to practice. Various types of simulators exist that can be used to test response under different visibility ranges. For instance, although the ideal range of sight must be 270⁰, certain simulators can be programmed to test the ability of the officers to handle a lower visibility range.

Bridge Equipment For Navigation And Control Of Commercial Ships

- Bridge Equipment For Navigation And Control

- For all maritime professionals

- 4 FREE Bonuses

- Read Instantly

- Guaranteed For 30 Days

Disclaimer : The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

About Author

Ajay Menon is a graduate of the Indian Institute of Technology, Kharagpur, with an integrated major in Ocean Engineering and Naval Architecture. Besides writing, he balances chess and works out tunes on his keyboard during his free time.

Read More Articles By This Author >

Do you have info to share with us ? Suggest a correction

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT

Leave a reply.

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

WAIT! Did You Download 13 FREE Maritime eBooks?

Sign-up and download instantly!

We respect your privacy and take protecting it very seriously. No spam!

- Yacht Sales

- Destinations

- Monaco Grand Prix

- About Ahoy Club

- Meet The Team

The Anatomy of a Yacht | Superyacht Terminology

Whether cruising with family and friends or enjoying an adventurous sailing trip, yachts can offer everything you need for the perfect holiday. Before stepping board, it can be useful to familarise yourself with the parts of a yacht to understand the language and terminology used by the crew onboard, and to appreciate how these impressive vessels work. From the keel to the sails, it's important to understand the anatomy of any vessel before setting out on a chartering journey.

The Parts of a Yacht - An Overview

Understanding the parts of a yacht not only improves your sailing experience but will also increase your appreciation of these powerful vessels. A standard yacht has several key parts, including a stern, hull, and bow. The stern, or aft, refers to the back the yacht, sometimes accompanied by a swim platform. On the other end of the vessel, the bow refers to the front of the yacht. The part of the yacht that floats in the water is referred to as the hull. Most traditional yachts have one hull, however catamarans are typically ‘multi-hull' having two points of contact with the sea.

Mischief superyacht was designed with an iconic French navy hull and white boot stipe.

Hulls – Materials and Design

As hulls are one of the largest components of a yacht, it is important that the design is intentional to withstand the elements on the ocean. The material that is it constructed of varies depending on the vessels size and intended use; it is common to see hulls made from wood, steel, or composite materials. Hulls play a crucial role is ensuring stability on board and a smooth journey as conditions on the ocean can vary.

Bridge & Bridge Deck

Port side & starboard side.

These terms refer to the left and right sides of a yacht; Port side refers to the left side, while starboard side is the right. A helpful tip is to remember the saying “there is a little bit of port left in the bottle.” This terminology is often used by crew in order to effectively communicate with their team in order to avoid accidents and safely navigate the seas, so you will likely hear these terms onboard your stay.

Lady Pamela’s large swim platform ideal for fishing or setting off paddleboarding.

Yacht Main Salon and Swim Platform

There is plenty of fun to be had in these two areas of a yacht. The main salon refers to the main living room onboard and is a space where yacht designers can showcase their personality in the design. Often featuring plush seating, stylish decor and high-end entertaining systems, guests can comfortably enjoy downtime relaxing and socialising in this area. The swim platform is exactly what it sounds like; it offers a convenient way to jump in to cool off and enjoy the water. When you feel it’s time to take a dip, the swim platform is the perfect spot to soak up the sun, enjoy the available watertoys , dip your feet in the ocean, or take a refreshing dive or snorkel in the sea.

All of these elements are thoughtfully designed by experts across the world to construct the magnificent yachts that we know and love. We encourage you to experience our favourite vessels for yourself through luxury yacht hire to appreciate the impressive design and craftsmanship. Our team is here to help you plan your dream holiday on board today.

You May Also Like

mischief superyacht

sirenuse superyacht

Luxury Yachts | Choosing the Right Yacht for You

Make an enquiry, make an enquiry.

- Career Advice

- Salary Guide

- Digital Dockwalk

AI and Smart Tech: The Future of the Superyacht Bridge

Nearly every year, the creative brain trust at Feadship’s De Voogt Naval Architects, Design Studio De Voogt, shares design projections leaping toward the future. These advanced concepts that go far beyond profile renderings are designed to inspire. Rather than imaginative artwork ungrounded by practicality, they include engineered solutions down to propulsion packages, safety regulations, general arrangements, articulating platforms, and glass and finishes concepts. The full plate of innovations — debuted at Monaco Yacht Shows with names such as Breathe , X-stream , Relativity , Royale , Qi , and Choice — aren’t necessarily expected to emerge on a single finished yacht, but emerge they do in elements, pushing a corner of the envelope here and tugging the edges of innovation there. The propulsion concepts for Breathe famously made their way to Savannah , for example.

The Pure Concept

The 81.75-meter Pure concept introduced at the 2021 Monaco show to oohs and ahhs for its smoothly curved, minimalist exterior and for its main and upper deck living spaces designed to blend the indoor and outdoor environments in a dramatic way. But there is another feature far beyond aesthetics that will cause lasting discussion, and one which is ripe for development: Pure ’s hidden bridge. By eliminating a bridge deck, the yacht gains a much sleeker, lower profile with all the knock-on effects that brings to motion and stability without compromising owner lifestyle. In fact, this concept is all about lifestyle — at least Studio De Voogt’s vision for how owners will want to live in the future.

Visual and social connections via open-plan architecture, tiered-yet-connected aft decks, and a massive three-story atrium stretching define the plan. Yes, we are assured, it could be built to full classification standards. As for the current design darling — sliding glass walls — there are a lot of them, and foldout platforms (yawn) on the lower deck. But let’s return to the hidden (Feadship prefers the term “concealed”) bridge. If the deck above main is the owners’, and the forward main deck is a tender garage, where is the wheelhouse? Actually, in terms of stability, it’s in one of the best places on the ship — low, just slightly forward of amidships and offering incredible adjacencies to crew areas and mechanical spaces.

What’s missing is the 180-degree wall of windows to see through when you drive the boat. Take a moment while your brain wraps around that concept.

The first point is to understand that this is NOT a concept for a remotely controlled yacht. Pure has a full crew just like any other vessel of her tonnage and horsepower. This concept will, however, take a big leap into the use of electronics and computational power for enhanced situational awareness on the bridge. Instead of the baby steps of a heads-up display here or there, or an instrument overlay on a single chart screen there, this is the entire kit synced to work together in real time. If it sounds like a futuristic Star Trek Enterprise bridge, you will be surprised to know this “concept” is already in operation aboard commercial and military ships — submarines have no bridge windows after all, and neither do tanks.

- Is ECDIS Just Another Charting Program?

Imagine the “bridge” has become a command center that’s like a theater in the round with Google glasses. And like Google glasses, it utilizes sensors and cameras and artificial intelligence that analyze all the data in microseconds for situational analysis. In addition to input from onboard sensors, cameras, and thermal imaging, GPS, weather and sea state data, ECDIS, LIDAR, RADAR, and SONAR, an almost unlimited amount of data could be added to the stream. This is currently being done on tugs, ships, and coastal ferries in European waters that are being helmed either full-time or during harbor maneuvers by remote fleet command centers assisting onboard crew.

By eliminating a bridge deck, the yacht gains a much sleeker, lower profile with all the knock-on effects that brings to motion and stability without compromising owner lifestyle.

This is the sort of setup that would support totally unmanned cargo or tanker operations or drones. While the fleet command systems in operation may also make use of Virtual Reality simulation, the Studio De Voogt concept does not rely on virtual reality or shore-based captains, but on onboard crew who manage all the tasks — just without looking out windows from prime real estate.

“The concealed bridge concept could be used on vessels of all sizes, but will have the most benefit, I think, to the under 500 GT yacht because it is difficult to arrange a main deck master that has forward views and deck access. Owners these days want their cabin with views, so you would have to make the master aft on the bridge deck or add another deck above, but within your tonnage,” says Tanno Weeda, who along with Jan Schaffers, masterminded the concept for presentation in Monaco. They have well-developed plans for the concept at 1,800 GT and 3,000 GT.

Part of the value in presenting the concept was to obtain crew feedback. Did they get that?

“Oh yes,” says Weeda. Contradicting my suspicions, he notes, “The captains were not that negative, especially the younger ones.”

Schaffers notes that the sentiment seemed to be, “The yacht is for the owner and I am there for the owner, and if this makes it better for the owner, I can do it.” Weeda adds that they were very attuned to crew feedback. “We need the input from the crew to make sure we make the yacht work for the client,” he says. “The most important thing they asked for was wing stations,” says Weeda, which, along with a flying bridge on the sun deck, they could already point to in the plan. Wing stations, a stern station, and/or a portable helm pack would be used for docking or anchoring maneuvers and then disappear. They highlighted that the concealed bridge preserves owner and guest privacy on fore and aft decks — no need to set the helm aft or extend a brow to shield a Jacuzzi or lounge on the deck below from wheelhouse view. And, unlike the current mindset that the bridge needs an open view forward (for most of maritime history, a vessel was controlled from a position aft) a fully integrated smart bridge can be located virtually anywhere on the vessel.

This could be a game changer not unlike that which took place when engine rooms were first moved aft of amidships, completely revamping lower deck accommodation layout options or when beach clubs moved forward from the stern with folding terraces port and starboard instead. They said there are two active discussions with clients for this concept at present.

- How New Satellite Tech Will Affect Yacht Internet Connectivity

Adapting the Concealed Bridge

As Schaffers and Weeda explained, the Pure concept of the concealed bridge can adapt to each project and would differ if the intention is that the captain and watch officer work alone or in teams. In their initial concept, they made it a hub of crew life and completely rethought crew movement paths around the yacht. They noted immediate benefits to the scheme such as dedicated radio rooms — a feature often eliminated (along with a crew dayhead) to preserve more owner real estate on an upper deck. “Another feature is that you can combine things with this space, such as a place to hold crew meetings or training. It shortens the distance dramatically between command and engineering spaces and off-watch crew in case of an emergency,” Weeda comments.

On the other hand, while in port, the wheelhouse sometimes becomes a crew hangout space or a private place to write an email or work on an online course. They said that would need to be considered in the GA to ensure crew welfare is maintained. And of course, whether it is going to be open to guests or not would affect its size and amenities. Both Weeda and Schaffers feel that it would be of high interest to guests when the yacht is underway, or when discovering what travel or activities were planned for the day as shown on large display screens.

The command center presented with Pure is not unlike the training simulators familiar to captains and aspiring officers with work zones arrayed under monitors displaying input from cameras and electronics. A large, curved monitor could display a full 270-degree view of the environment in real time with augmenting information popping up as appropriate on the “picture window” while engine and systems data stay displayed on individual monitors.

Conforming to Code

But how would this mesh with LY3? For the answer, we turned to Section 18.2 of the Red Ensign code on bridge visibility, which directed us to SOLAS Chapter V, sections 15, 19 22, 24, 25, 27, and 28. It turns out such an idea is not specifically prohibited. A view of the sea and horizon from the con is discussed but it does not say where that con has to be or if it can be the flying bridge or wing stations — which are in fact mandated along with their degrees of visibility fore and aft. It is stated that for vessels not less than 45 meters, the view of the sea surface from the con position cannot be obscured by more than two ship’s lengths or 500 meters, whichever is shorter. Bow cameras and LIDAR certainly can be expected to give a superior view to that.

In one section, a range is given for the height of windows as measured from floor and overhead and their maximum incline, but nowhere does it say you must have windows, or how many. In fact, in commercial practice now in harbors in northern Europe — Norway being the leader — the con is often an array of screens at fleet control where a shoreside captain with every imaginable sensor and perspective view at his or her disposal actually takes the helm of in- or outbound ships. The benefit to this augmented intelligence (AI) system at night or in poor conditions over a ship-bound pilot is obvious.

Rolls-Royce and Kongsberg — leaders in autonomous ship development — debuted these systems six years ago. Iiro Lindborg, General Manager, Remote & Autonomous Operations for Rolls-Royce, says, “AI is undoubtedly one of the most significant advances made to-date in terms of ship navigation safety. It provides bridge personnel with a much greater understanding of the ship’s surroundings.” The company expects passenger ships to be one of the biggest markets.

In the Far East, Japanese ship specialist Mitsui is installing an AI system aboard a 165-meter passenger ferry, Sunflower , which operates between Kobe and Oita, Japan.

On a slightly different note, in the U.S., Sea Machines introduced SM200, moving control of towing and harbor vessels outside their wheelhouses. Captains using the SM200 have propulsion and steering control in their hands, wherever they might be on board. It was approved by the ABS and the U.S. Coast Guard for use in articulated tug barges in early 2020. While this gear is designed to be used by a captain on deck, this is a precedent-setting step in the break from a fixed helm position.

With the power of systems like these, as well as increased acceptance for autonomous ship operations, more change is inevitable for yacht control stations, and if yachting follows military and commercial shipping, the buzz will be all about augmented intelligence or enhanced situational awareness for captain and crew. Feadship is betting that one radical idea can lead to safer and more efficient operations while at the same time enhancing owner and guest lifestyle.

This feature originally ran in the July 2022 issue of Dockwalk.

More from Dockwalk

Most popular on dockwalk.

What Is The Bridge On A Ship?

Ever wondered where the control station of massive ships is located where it is operated from? Ships are enormous vessels that can stretch hundreds of meters in length and carry thousands of tons. It is critical to be able to operate and maneuver such a massive vessel safely.

The bridge is a vessel’s principal control center, from which the captain and officers can manage the whole vessel’s operations. It is usually placed in a position with an unobstructed view and immediate access to the ship’s vital controls.

In this post, Let us look into how the bridge has evolved, what are the primary functions it plays, the basic design of the bridge, its many parts, and the rules that must be adhered to.

The History Of The Bridge On Ships

Historically, the bridge was linked to the paddle or wheelhouse, which contained the steering machinery. This name was given because it resembled a real bridge.

Even when technical advances rendered paddle wheels obsolete, the term “bridge” persisted. The captain is always the master of the bridge, and he retains control and accountability of the vessel when on board.

The Bridge: A Central Control Hub

The bridge is a ship’s primary control center, serving as a hub for crucial operational activities, communication, and decision-making. The work environment and activities are highly complex and safety-critical because the bridge is situated on a structure that frequently functions in severe and unpredictable conditions.

A vessel’s bridge houses the major steering equipment, navigation charts, communication systems, engine control, and other elements. Furthermore, some bridges feature neighboring bridge wings that house the stern and bow thruster machinery. These wings extend beyond the main bridge chamber and offer an unimpeded view of the surroundings.

An officer of the watch is always present on the bridge, controlling the ship’s movements and communicating with the engine room . To avoid any untoward incidents, an officer and a lookout must typically be present on the bridge.

On the bridge, a safe is used to store the ship’s papers, permits, critical documents, passports, cash for emergencies, etc. To prevent pirate attacks, the bridge’s entry portals are frequently strengthened and commonly equipped with bulletproof glass.

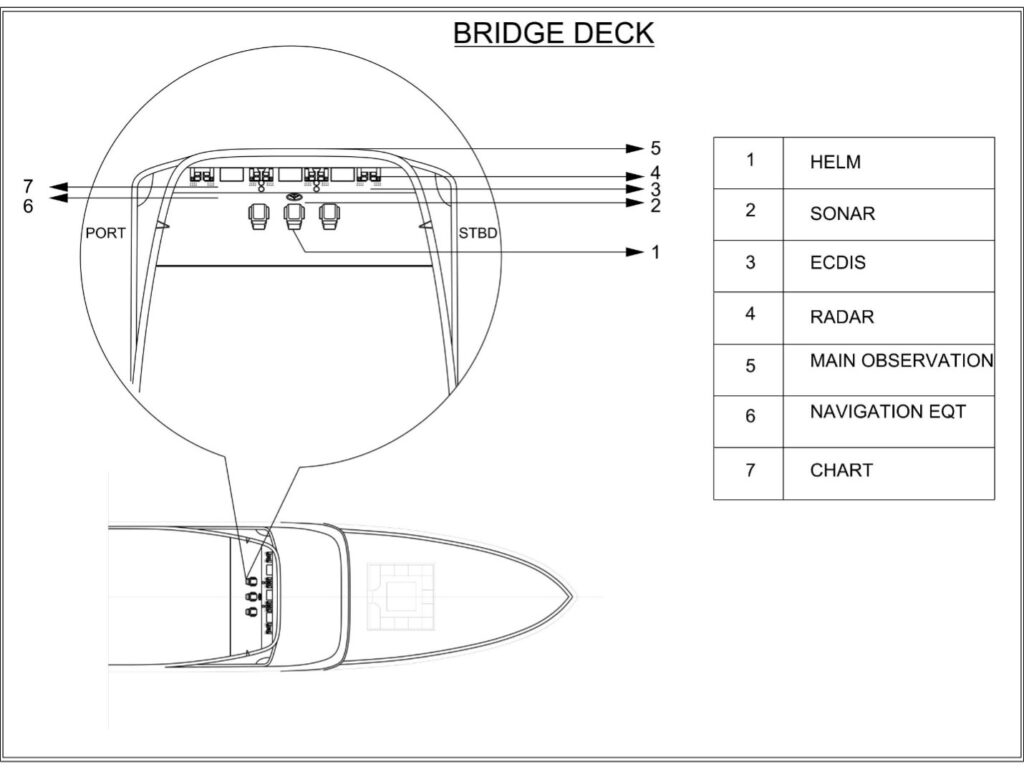

Bridge Design And Layout

The design of the bridge will vary depending on the ship. But it should be noted that the bridge arrangement generally adheres to the same fundamental design and layout regardless of the type of vessel.

A ship’s bridge is supposed to be its central control hub, offering an unimpeded view of the surroundings and quick access to all controls. The main goal of navigation must be achieved in terms of visibility despite the bridge’s abundance of electrical and navigational technology.

The bridge is roughly divided into two sections: the fore area, which is intended for clear observation, and the remaining area, which is for controls and communications.

The observation area is protected from storms and other bad weather by a wide glass wall that surrounds it at the front. Often, steel or aluminum frameworks are utilized to support plexiglass structures. Additionally, lowering shades are employed to ensure that visibility is not compromised by bright lighting.

The primary navigational, steering and communication apparatus is located in the remaining space of the bridge. Other controls can be used to remotely control different ship systems, for example, cargo or ballast systems .

The control area is incorporated into various console units that are arranged on each side of the bridges in a semi-circular pattern. This includes steering wheels and radar systems operated by ship officers .

A bridge will typically have a captain, a chief mate, a second mate, a third mate, competent seamen, and regular seamen depending on the type of ship.

What Are Bridge Wings?

Bridge wings are present in addition to the central observation deck. They are on the port and starboard sides, and their main function is to widen the visibility area, particularly during difficult maneuvers like port docking.

Additionally, they contain the controls for the separate bow and stern thrusters that are located on either side. Deep inside the hull, thrusters are propellers that provide the captain more control over the ship so they can make precise maneuvers and changes.

Depending on the type of ship, the bridge wings can be either open or closed. The wings are typically left open to allow for optimum visibility. To convey information back to the main bridge section, communication equipment can also be located on the wings. Only skilled seamen and watch officers are permitted access to the bridge wings.

Steering And Engine Layouts On The Bridge

Controls for the ship’s rudder , engines, and thrusters are located on one of the several consoles in the bridge. The chief engineer or the officer in the engine room has the main responsibility for engine control, but an officer from the bridge frequently gives orders to the engine room.

The propellers may also be turned in reverse thanks to an engine control unit, which also allows for a different range of speeds. The numerous engines on board frequently have their controls. There are bow and stern thrusters that enable a wider range of transverse precise motions in addition to the engines and propellers.

The bridge is where the controls for the rudder and thrusters are located, which are used largely to maneuver the ship. The rudder is designed to be able to turn 450 degrees to both the port and starboard sides. In the case of more advanced systems like azimuth or integrated propulsion systems, a larger command center is frequently used.

An intriguing technological advancement is the use of azimuthal propulsion systems, which let regular engines and rudders work together. They turn in practically any direction and achieve efficiency close to 100%. This eliminates the requirement for separate controls for the steering and propulsion systems. Controls on the port side are typically color-coded red, while those on the starboard side are frequently coded green. The officers and seamen can maintain control more easily as a result.

Navigation And Communication Equipment

A vessel’s navigation system is a vital part because it is the only way to transport it securely from one port to another. A Global Positioning System (GPS), Navtex receiver, Electronic Chart Display and Information System (ECDIS), radar systems, and communication channels are all considered to be basic navigational tools.

Charts that are used to plot routes are frequently utilized to regulate navigation. A GPS and compass system are used to make sure the boat stays on course. To maintain the bridge’s compartmentalization, the charts and equipment are kept in different places. Additionally, binoculars are utilized for sighting during the day.

However, the radar must be used to precisely position and navigate the ship when the weather is not clear, visibility is poor, or it is dark out. When utilizing radar, a range scale that takes the speed and nearby traffic into account must be employed. Ships weighing more than 10,000 gross tons are required to navigate and plot their path using two radars.

On such warships, automatic tracking aids (ATA), electronic plotting aids (EPA), and automatic radar plotting aids (ARPA) are also essential. Errors are also signaled by the same alarms that are used to warn about approaching collisions, equipment failure, etc. Onboard the ship, warnings are signaled through indicator lights in specific areas.

Drawbacks Of A Poorly Designed Bridge

Tasks performed by the ship’s crew and navigation team involve interacting with both people and technology (the various equipment and systems of the bridge and ship). Onboard the ship and with outside parties, this calls for engagement and communication between people and technology (e.g. port control, Vessel Traffic Service, surrounding ships, onshore facilities, etc.).

Technology-wise, the bridge is a complicated system. A merchant ship’s typical bridge equipment may include things like:

- an autopilot,

- conning displays,

- Automatic Radar Plotting Aid (ARPA),

- Electronic Chat Display and Information System (ECDIS),

- Dynamic Positioning (DP),

- Global Positioning System (GPS),

- Gyrocompass,

- various communication devices required by GMDSS

- and a combination of other systems and sensors.

A single bridge could be made up of dozens of pieces of equipment from many brands and suppliers. The design and layout ideas used by these companies for hardware and software components are often unique.

The crew may experience issues once the equipment has been built and integrated into a single working environment (such as the bridge), which calls for the employment of the equipment in tandem. Consequences for the crew have been demonstrated as a result of inconsistent design across these many pieces of equipment and interfaces, and it has even been suggested that such inconsistent design may have contributed to maritime accidents.

Bridge Rules And Guidelines

Vessels must adhere to the toughest protocols while at sea to guarantee that SOLAS and IMO requirements are met. The bridge and its equipment must adhere to regulations because the bridge controls the whole ship. The following are some of the most common rules that a vessel must follow,

- The bridge needs to be situated so that it has a clear view both forward and behind it for navigational purposes. The officer on watch (OOW) must also have a minimum eyesight of 2550 and at least 112.50 visibility on both the port and starboard sides.

- The bridge wings must be able to see the side of the ship with 1800 on one side and 450 on the other. The minimum unobstructed visibility for the officer in charge of steering is 600 on both sides.

- Ships with a gross tonnage of more than 10,000 must have a single X-band radar operating at a frequency of 9 GHz. This is by IMO navigation and steering standards.

- Alarms should be installed in every zone on the ship in case of any emergencies. These alarms signal various equipment failures on the bridge. In addition, the bridge is informed immediately of any failure or damage in other areas of the ship. After 30 seconds have passed with no response from the officer on duty, a backup alarm is sounded. This backup alarm signals the need for help by sounding in the offices, mess, and cabins.

- Each piece of equipment used onboard must be IMO certified and have completed a battery of tests designed to determine how durable it is and how long it will continue to work. Fire extinguishers, flares, and distress beacons are kept on the bridge for safety’s sake.

- In case of an emergency, the bridge can activate a network of water pumps positioned all around the ship to prevent any other vessel from approaching too closely. Additionally, specialized marshals who keep their weapons on the bridge are frequently hired to provide contracted security.

What Is A Bridge Simulator?

Giving a brand-new recruit command of an entire vessel is not practical for training purposes. Bridge simulators are useful in situations like this. It takes substantial training on the bridge to be able to sail through a body of water safely. Before ever taking control of the bridge, officers usually spend years perfecting their abilities.

The majority of training facilities and institutions have their simulators, allowing recruits to train on them before being sent to sea. Although they are much larger, they resemble aviation cockpit simulators. Additionally, several shipping firms provide specialist simulation software that may be configured to show a variety of scenarios.

When you enter a ship’s bridge, numerous activities are going on. Even the use of the word itself has a rich history, which many of us probably never consider. But whether you’re on a big commercial ship or a little private one, it helps to know the past. Understanding the layout of the bridge and how it will be used is crucial to operating any vessel as intended.

- Recent Posts

- Responsibilities of a Fourth Engineer on Cargo Ships – September 10, 2024

- The Role of Cargo Ships in Global Trade – August 22, 2024

- Report: Yang Ming’s YM Mobility Explosion at Ningbo-Zhoushan Port – August 9, 2024

About the author

I worked as an officer in the deck department on various types of vessels, including oil and chemical tankers, LPG carriers, and even reefer and TSHD in the early years. Currently employed as Marine Surveyor carrying cargo, draft, bunker, and warranty survey.

Latest posts

Is Maritime Security Necessary on Modern Ships?

It’s vital for ships to stay vigilant. Isolation from land means having no backup or protection for miles, making them vulnerable to attacks and other threats. Equip modern ships using modern maritime security methods.

Responsibilities of a Fourth Engineer on Cargo Ships

A Fourth Engineer on cargo ships oversees engine room operations, machinery maintenance, and ensures compliance with regulations like MARPOL.

The Quality Control Process in Marine Manufacturing

Companies in the marine manufacturing space must have tight and effective quality control processes. What steps should an effective quality control process include?

The Open-Bridge Convertible Versus the Enclosed Bridge

Article Courtesy: marlinmag.com | Originally Published: 11/30/2021 | Click here for original article

The choices are varied when deciding if your next fishing boat will sport an open flybridge with a hardtop and crystal-clear enclosure or, perhaps, you’ll opt for a climate-controlled enclosed-bridge command station instead. Although many skippers take sides when it comes to their favorite design, and for no shortage of logical as well as personal reasons, more often than not, it is the owner’s choice that finally decides the matter. Studying the purpose and accommodations of the layout provides a definite view of the benefits, attributes and limitations of each style.

The open bridge today is a far cry from its origins as simply a place to operate the boat with heightened visibility, in spite of being totally unprotected from the environmental elements of sun, wind, salt spray and rain. I recall seeing photographs of old boats from the 1940s and ‘50s with flybridges that were minimally equipped, with just a single chair, the wheel, engine controls, and wiring fed through a tube in the roof from the lower station. On the deck, a glass port offered the captain a view of the engine gauges below on the console, while the front and side bridge wings were made of canvas that was secured to metal piping screwed to the roof. Chrome-plated bronze step plates on the house sides and the piping above served as grab points, providing passage to the bridge from the cockpit. Utilitarian, yes, but that’s the way it was. These days, the flybridge has thankfully evolved (at least) tenfold, and has also enhanced what was once a simple platform with a multitude of critical features that a captain needs to do his multitasked job successfully and efficiently.

Design and Function

Operator visibility for fishing and safe navigation in all weather and sea conditions is crucial, and the helm layout on a flybridge reverts back to design and function. Running a boat might look like fun to the uninformed, but in truth, steering a 60-footer that displaces almost 100,000 pounds and cruises along at 30-plus knots is both exhilarating and tense at times due to changing ambient conditions. Undivided attention is mandatory, and a properly designed bridge is meant to help get the job done safely.

Two prevailing styles include the centerline helm station with a walkaround center-console featuring passageways forward to both port and starboard, and the peninsula design that favors passage to one side. The choice is often dictated by the size of the boat, but especially by the width and length of the deckhouse. A flybridge with wings that extend to the outmost measurements of the deckhouse will arguably offer more square footage for seating, moving about, storage and other appointments. But either way, the most important factor is that when you stand behind the wheel and operate the boat through all throttle settings, the view is unobstructed looking forward and side to side, as well as down into the cockpit below.

On larger vessels, it is not uncommon to incorporate a raised helmsman platform to boost the height of the operator for enhanced visibility forward. Savvy boatbuilders sometimes take advantage of the platform to include storage inside the shell. The amount of helm seating is a choice that needs to be decided, but the decision should take into account more than just the number of chairs. Is there sufficient room to easily access the fishing rods stowed along the aft belly rail without disturbing the operator, or a passenger who is already seated? Will a third chair crowd the access to the flybridge ladder? Is there room for grab rails or a hatch for secure movement up and down? And finally, how many people does the captain really want on the bridge anyway? Likely as few as possible.

More alternatives are conveyed in selecting the console layouts. A center-console helm can leave room for flanking lounges that also conceal storage, such as a dry space for loose gear or safety items. On long runs, the lounges are particularly inviting for relief crew to sack out. Removable backrests can be built into the lounges so occupants can stretch out and face forward while the boat is underway, or reversed to face aft, transforming the lounge into a jump seat for spotters to watch the spread. Space in front of the console can be utilized to include another lounge, a table with built-in storage, a big freezer, a refrigerated drink box, and/or a sink outfitted with a freshwater outlet and a washdown hose for rinsing salt from the enclosure for increased visibility after a long, wet run, or for spraying down the bridge area on the way back to the dock. Forward is a cavernous stowage area in the brow that often houses air horns and air-conditioning units.

The peninsula-style helm is equally functional, although the configuration of storage and lounging might be quite different. The bridge deck is wrapped in three-sided enclosure panels for visibility and weather protection, while vents in the top portion provide a fresh breeze while still protecting the bridge occupants from direct spray and rain.

Electronics take up most of the space in both of these helm layouts but do allow for maximum customization. Some consoles are designed with angled pods to flush-mount displays beneath a clear acrylic panel with other accessories, switches and controls in full view while offering the equipment protection from the elements. This arrangement generally allows sufficient access inside the console to reach wiring, connections, steering and other systems, as well as storage for bulkier items such as life jackets and throw rings. Another popular approach is to mount the electronics so they rise up from inside the console with an electric or hydraulic lift. However, this also means that the equipment is exposed to the elements while in use. To prevent engine instrumentation and other equipment from crowding the helm but still be in reach and visible, drop-down compartments or molded-in overhead pods are commonly installed in the underside of the hardtop. Teaser reels and other electronics also find homes in the hardtop directly above the captain’s chair.

Enter the Enclosed

The evolution of the open flybridge has made it a seagoing work of art that can check every box for fishing prowess on the edge—to raise, hook, and release or boat a trophy—but the constant exposure to hot and cold environments, the sound of whipping wind, sheets of spray crashing against the enclosure, engine noise, vibrations, and the banter on the VHF radio all take a toll on the captain in the form of accumulated fatigue. And while there is no denying the popularity and purposefulness of the open bridge, there might come a time when creature comforts and quiet time become sought-after issues, especially for programs whose run times to the fishing grounds are extended. It is here where the enclosed flybridge becomes a significant player.

Unlike an open-bridge design, which is truly the sum of numerous individual parts fastened together, an enclosed bridge is generally singular in form and function. The molded roof, windshield mullions and bridge superstructure become a single unit with a solid, watertight door on the bulkhead that opens out to a bridge deck to access the cockpit. The control station on the enclosed bridge is forward on the centerline, and the closest thing to the helmsman’s eyes is a solid-glass windshield that delivers uncluttered, unobstructed visibility. Electronics surround the steering wheel for easy viewing and operation, and the hardtop overhang helps to control glare and water reflections.

One of the most important accessories at the enclosed-bridge helm is a camera monitor that keeps the operator informed about conditions around and throughout the yacht. Seating options are varied, but a popular layout features an adjustable helm seat with passenger seating or lounges to port and starboard. Another endearing aspect of the enclosed bridge is the spacious area aft of the helm, which often gets tagged as a second salon with a sofa or dinette. A line of cabinetry opposite the lounge seating houses accoutrements, including refrigeration, a sink, an entertainment system and additional storage. And almost always, a staircase is installed and directly connected to the salon on the main deck.

Back when I ran an open-bridge convertible, I filled in for a friend who owned an enclosed-bridge boat to run a nighttime bluefish charter. I had plenty of experience running at night with my boat, but my first trip operating from an enclosed bridge at night was all it took to realize some of the benefits of this design. We caught plenty of fish for the charter group that evening, but I was more impressed with the quietness of the ride to and from the offshore grounds. Even the ringing 6-71 Detroits sounded well-mannered that night, and unlike my open bridge, where I was always damp with salt air and exhaust mist, I was dry, warm and comfortable. The experience left me envious, thinking of my next several Hudson Canyon trips and the one-way 75-mile jaunt from New Jersey’s Manasquan Inlet, a run that always seemed longer on the way home.

The comfort afforded by a climate-controlled enclosed bridge is unchallenged by the ride in an open-bridge boat, particularly in riotous seas or inclement weather. And without having a deck to wash, an enclosure to chamois or seat cushions to wipe down, taking care of the interior and exterior of the enclosed bridge is a snap; a quick pass with a vacuum, a microfiber cloth to wipe down the woodwork, and a generous outside rinse with Spot Zero water is usually enough to remove salt and keep the windows clear and spot-free.

Changes in Design and Strategy

Fishing from an enclosed bridge can be quite a different story than fishing from an open bridge, and it does require significant changes to your strategy. Capt. Mike Hunter of Princess Lily , a Palm Beach, Florida-based 66-foot Viking enclosed bridge, splits his time between fishing from the aft helm station on the bridge deck and from the tuna tower. With remote screens at both the aft helm and in the tower, he can monitor his electronics and operate the teaser reels trouble-free. The crew use headsets to help with back-and-forth communications between the helmsman and the cockpit, relaying and receiving information to minimize yelling and confusion. Since his bridge-deck helm is on the starboard side, Hunter likes to fight his fish in a right-hand turn because he can see the angler, the rest of the crew and the fish more clearly. And even though he can see through the aft window and through the windshield from inside the bridge, he still is concerned with the restricted view of the port side and will move around regularly to verify that no traffic is nearby. Training himself to be more cautious in looking out for small boats keeps him alert and his anglers connected to more fish. The view into the cockpit, however, is spot-on, and he can see everything at a glance and not just settle for watching the rod tips. Similarly, by looking aft when in the tower, he can observe, advise and direct his anglers to where their baits need to be. To make his top-flight work more accommodating, he also has equipped the tower pod with a removable, wraparound clear panel that extends vertically from the top of the pod to the buggy top to counter those long hours of cold northerly winds when the sailfish are biting in South Florida.

Brielle, New Jersey-based skipper Capt. Bill Sevistakis has won and placed in mid-Atlantic marlin and tuna tournaments while running a 65-foot Hatteras enclosed bridge with a tower, and a 74-foot Viking enclosed bridge with no tower. He appreciates the comfort, flexibility and convenience that the enclosed-bridge style offers more than the many open-bridge convertibles he has operated in his long career in the Northeast to the Caribbean. As a youngster in St. Croix, Jamaica, he worked with his grandfather, who fished an enclosed-bridge boat, and quickly noted the benefits of not wearing the ocean at the end of the day.

Like any design, the enclosed bridge is not without shortcomings. Sevistakis points out that storing fishing rods can be an issue because the enclosed bridge often lacks those long seating benches that are seen on open boats, while Hunter notes that the space inside the enclosed bridge can be limited when it comes to the conveniences of a full-size food or bait freezer like those typically found on big open-bridge convertibles. But both skippers do agree that on long-range trips, the enclosed platform provides the quiet comfort that many are after.

With so many excellent choices on the market from a variety of production and custom builders, the choice really hinges on how you plan to use the boat, as well as your fishing style, the prevailing local weather conditions and more. You really can’t go wrong with either design, just be sure to evaluate your needs and educate yourself of the options.

Option No. 3

Proving that the sky is indeed the limit in big enclosed-bridge convertibles, one option is installing an open flybridge above the enclosed bridge in lieu of a tuna tower. Known as a skybridge, a ladder on the aft bridge deck leads to a peninsula-style helm with pedestal seats, and a scaled-down lounge. A fiberglass hardtop and a three-sided enclosure provide weather protection in what might be called the best of both worlds—and then some.

This article originally appeared in the December 2021 print issue of Marlin.

Search here

Research & environmental, roffs™ oil & gas.

Shipping, Tow, and Rig Move Forecasts Current and Eddy Forecast Samples

Commercial Fishing Analyses

Recreational fishing analyses, recent articles.

Big Blue Marlin Dominate Final Day of the 2024 MidAtlantic

Louisiana Wildlife and Fisheries Commission Expands Shark Harvest Opportunities

Northeast U.S. Spring Preview 2024: CONDITIONS ARE WARMING UP

How to Fish for Wahoo Using Slow Trolling Speeds

- Nautical Dictionary

- Connect on WhatsApp

Bridge wing(s)

Nautical term: bridge wing(s), definition of bridge wing(s).

Bridge wing(s) refer to lateral extensions to a vessel’s bridge. These extensions enable the bridge crew to have a direct line of sight beyond the hull side. For instance, during navigation through narrow waterways, the bridge wing extensions allow the crew to maintain a clear view of the surrounding area, ensuring safe and efficient navigation.

Explore other nautical terms:

- Painting beams

- Marlinspike

- Rudder truck or case

Head back to the Nautical Dictionary

Ready for your next big adventure?

Book a tour with highlight charters today.

Take a Tour With Us!

Sunset Sailing Experience (4 Hours)

Swim, Snorkel, Paddle (4 Hours)

Whale Watching Tour (4 Hours)

Yelapa Town Waterfall Day (10 Hours)

Yelapa Town and Waterfall Overnight (2 Days)

Surf, Snorkel, Paddle (8 Hours)

Recommended reading.

Want to learn more about life on the water? Check out one of these books:

Boatowners Mechanical and Electrical Manual 4/E

Deep Shadow (The Deep Series Book 1)

Barbarian Days: A Surfing Life

- Crew Accommodation

- Crew Agencies

- Lifestyle Management & Concierge Services

- Limousines & Car Hire

- Marinas & Ports

- Maritime Lawyer

- MCA Approved Doctors

- Restaurants

- Yacht Agents

- Yacht Brokers

- Yacht Charter Companies

- Yacht Management Company

- Yacht Provisioning Companies

- Yacht Refit & Repairs

- Yacht Sales

- Yacht Training Facilities

- Yachting Equipment

BNWAS and how it affects your yacht November 5th, 2014

BNWAS and how it affects your yacht

BNWAS - Bridge Navigational Watch Alarm System is a safety system made mandatory in amendments to SOLAS (Chapter V, regulation 19). Its purpose is to monitor activity on the bridge and detect inactivity of personnel on watch and then alarm and alert the master or other qualified crew, thus avoiding a potential maritime accident.

BNWAS will affect all yachts greater than 150 GT that are built to the Large Yacht Code and the Passenger Yacht Code and must be installed on all newbuild vessels with keels laid on or after the 1st of July 2011. This equipment is considered to be part safety equipment and it will therefore be surveyed as such.

Type approved BNWAS must be fitted or retrofitted:

- To yachts of 150GT and greater and all vessels constructed as per the Passenger Yacht Code irrespective of size that are constructed after the 1st of July 2011.

- No later than the first survey after 1st of July 2012 to All Passenger Yacht Code vessels that were constructed before the 1st of July 2011.

- No later than the first survey after 1st of July 2012 to yachts of 3000GT and above that were constructed before 1st of July 2011.

- No later than the first survey after 1st of July 2013 to all yachts of 500GT and above, but less than 3000GT that were constructed before the 1st of July 2011.

- No later than the first survey after the 1st of July 2014 to all yachts of 150GT and above but less than 500GT that were constructed before the 1st of July 2011.

When installing the BNWAS to your yacht, you should consider that activating the reset must be possible without having to move from a proper lookout position. These reset buttons could therefore be located:

- At the helm or conning position.

- At the navigational station

- On the bridge wings

The size of your yachts bridge may allow you to have a single reset button covering all of the above locations but take into account that it should it should be possible to reset the BNWAS during manoeuvres without having to leave the manoeuvring station (which may be a bridge wing). The IMO has agreed that other methods are allowed to reset the BNWAS system and these may include external inputs from other equipment such as the radar or chart plotter that will register the alertness of the watchkeepr, and or certain speech recognition sensors, inputs from motion sensors or the watchperson performing a single action on a BNWAS device.

Note that it should not be possible to cancel alarms on the system outside of the areas that are considered to be the proper lookout position.

Yachts will be required to use the BNWAS whenever the vessel is underway or whenever the ships heading or track control system is engaged, unless inhibited by the master. Although most BNWAS are equipped with an automatic mode allowing it to be automatically activated when the autopilot is on, this mode is not considered to meet the requirements of the IMO and so operation in this mode should be avoided.

When the BNWAS goes into alarm because it has not been reset by the duty watch person, the 2nd alarm is to sound in bridge officers cabin or the masters cabin after 15 seconds of the failed resetting by the watch person. The second alarm sounder can be located and selected between numerous cabin, but it must not be possible to isolate the alarm to the selected cabin/s.

If the second alarm is not reset within 90 seconds, the third alarm must sound to further crew and this can (but not necessarily) be performed through the general alarm.

For further reading, please reference your SOLAS manual, chapter 5, regulation 19 and the MCA Large Commercial Yacht Code (LY3) .

- News & Trends

- Water, Electricity

- Yacht control panel

- Cramm Yachting Systems BV

Exhibitions

Yacht control panel bow stern touch screen.

Characteristics

Description.

Meet this supplier at the following exhibition(s):

19-21 Nov 2024 Amsterdam (Netherlands) Hall 09 - Stand 209

- Yacht monitoring and control panel

- Touch screen monitoring panel

Boarding Passerelles

Cramm passerelles are the perfect, safe and quick system for boarding your superyacht. Our passerelles are designed to perfection, providing you with an elegant and timeless entrance for your guests and crew.

You can select from a wide range of standard modular solutions or fully-customised boarding equipment to meet your wishes and demands. For both options, we use the best available materials, deliver total service and assistance during the entire project, and guarantee maximum safety while operating.

Accommodation Ladders

Cramm boarding ladders are the perfect, safe and quick solution for boarding your superyacht. Our ladders are designed to perfection, providing you with an elegant and timeless entrance for your guests and crew.

You can select from a wide range of standard modular products or a fully customised boarding ladder to meet your wishes and demands. For both options, we use the best available materials, deliver total service and assistance during the entire project and guarantee maximum safety while operating.

Deck Cranes

Cramm deck cranes are the ideal cranes to hoist your equipment such as tenders, jet skis and submarines to and from your super yacht. Our cranes offer maximum efficiency in that they can be used for cargo handling applications as well as rescue boat and life raft hoisting.

Depending on your requirements and ideas, Cramm can supply a crane to match every need. For example, an impressive project we completed was a custom-made deck crane with a hoisting capacity of SWL 15 tonnes and a teak gangway on top.

Sliding Beam Cranes

Our overhead sliding beam cranes are designed to lift equipment such as tenders, rescue boats, life rafts, jet skis, submarines and cars safely and easily in and out of the superyacht. Cramm’s range of overhead cranes includes various types from single-sided and parallel set-up to outward telescopic.

We have also developed a special type of sliding beam crane for lowering items into the water to port and starboard. The development of special profiles for all our sliding beam cranes ensures that every crane has a minimum height, a key benefit compared with many other sliding beam cranes on the market.

Doors and Hatches

Opening up the side of the yacht offers a huge amount of additional possibilities to the yacht, such as tender storage, beach clubs and others. The design of the yacht door is based on a 3D model of the client’s yacht, and custom-made in aluminium, steel or stainless steel.

The main difference between a door and a hatch is that a door is located vertically while a hatch is located horizontally. The outside of the doors follows the shape of the hull, while the inside is level and straight. The doors can be electric or hydraulically driven and opened horizontally or vertically to give maximum flexibility.

Heligrid Landing Platform

The Cramm helicopter landing grid system, combined with a harpoon rapid securing system, aims to secure a helicopter to the flight deck immediately on touchdown by engaging and locking the helicopter harpoon on to a landing grid in the flight deck.

Satisfying the most stringent NATO Stanag 1276 requirements, the system can be used for various types of helicopters, including defence and rescue helicopters. It prevents movement of the helicopter on the flight deck under the influence of large waves and strong side winds, and allows the helicopter to land and take off safely while at sea.

Balconies and Platforms

Yacht platforms and balconies are ideal elements to expand the exterior space and connect it with the interior, providing easy water access and space to enjoy the view. The platforms or balconies can be equipped with many features, creating a luxury outdoor living space close to the water.

Such platforms, also known as beach clubs, compensate for the lack of easy water access and offer the client options such as swimming, sunbathing and scuba diving directly from the yacht. We provide customised folding and/or sliding systems integrated into the vessel’s hull or superstructure.

Telescopic Masts

Cramm can supply all your requirements regarding navigation masts, antenna masts, flag masts or light masts. Cramm telescopic masts have many advantages over standard masts. When the telescopic mast is retracted into the deck, it gives the deck that superyacht sleek and luxury look.

Cramm masts are manufactured from stainless steel, with visible components receiving an elegant brushed finish. If preferred, the whole mast can be faired and painted in the same quality paint as the yacht, to give it that extra designer look.

Bridge Wing Stations

When morring the superyacht, the captain cannot always oversee the situation from the bridge which can result in dangerous situations. Bridge wing control stations offer that extra visibility and overview of the situation to create maximum safety when docking.

The return on investment of using a wing control station can be significant. Preventing one accident during the lifetime of the superyacht will generally cover the cost of the wing control station.

Boat booms are located on the side of the yacht and are used while a superyacht is anchored to attach smaller boats and tenders on the yacht. This prevents that the smaller boats or tenders can hit the yacht. Boat booms are fully automatic and can be controlled by means of a push-button-panel or a radio remote control.

The boat booms are usually placed near a tender garage or boarding platform. They are non, single or double telescopic systems depending on the requested reach and available storage length. Boat booms can be delivered with a box/trunk for welding in the yacht structure.

Wärtsilä Nacos Platinum bridge systems selected for two new mega yachts

The technology group Wärtsilä has been contracted to supply its Nacos Platinum integrated bridge system for two new mega yachts; one an 85 metre long vessel and the other 91 metres long, being built in Greece. In addition to the systems, Wärtsilä will also provide the project management, engineering, pre-wiring of the consoles and system commissioning services, thus delivering a complete solution. The orders with Wärtsilä were booked in March and July 2017.

The new and advanced bridge console concept for these vessels includes an integrated navigation system (INS) with compass and latest technology navigation sensors, and an integrated automation system with power management functionality. A state-of-the-art propulsion control system and a radio communication system are also included. The overall bridge design has been customised according to the specific requirements for these yachts.

“The Nacos Platinum integrated system is based on the very latest technologies and is in accordance with known and anticipated rules and regulations. Furthermore the system is supported throughout the entire lifecycle to ensure long-term usability and to provide real customer value. Throughout these project negotiations we have worked closely with our local sales and service partner, Environmental Protection Engineering located in Piraeus, and their cooperation has been much appreciated,” says Maik Stoevhase, Director, Automation, Navigation and Control & Integrated Systems, Wärtsilä Marine Solutions.

The modular bridge concept hosts Multipilot multi-functional work stations for indicating the network radars, the electronic chart display and information system (ECDIS), conning, and the integrated automation on the main console. On both bridge wing stations, Datapilot screens will be installed. The enhanced software features of the Nacos Platinum system are designed to promote vessel safety, especially when sailing in unfamiliar waters.

A large 46 inch ECDIS work station will be installed in an adjacent ship office for navigational voyage planning and crew briefing purposes. The system will be connected to the Nacos digital data network enabling planned routing to be accessible from the bridge work stations via an integrated Trackpilot system.

Wärtsilä’s extensive offering for the luxury yacht market, including the Nacos Platinum system, can be seen at stand QS 88 at the Monaco Yacht Show, being held from September 27 to 30.

Link to images Caption: State-of-the-art navigation consoles are included in the complete bridge system.

Media contacts:

Mr Bernhard Jungsthöfel Sales Engineer, Electrical & Automation Wärtsilä Marine Solutions Tel: +49 4088 2522 87 [email protected]

Ms Marit Holmlund-Sund Senior Manager Marketing, Communications, Marine Solutions Wärtsilä Corporation Tel: +358 10 709 1439 [email protected]

Wärtsilä in brief: Wärtsilä is a global leader in advanced technologies and complete lifecycle solutions for the marine and energy markets. By emphasising sustainable innovation and total efficiency, Wärtsilä maximises the environmental and economic performance of the vessels and power plants of its customers. In 2016, Wärtsilä's net sales totalled EUR 4.8 billion with approximately 18,000 employees. The company has operations in over 200 locations in more than 70 countries around the world. Wärtsilä is listed on Nasdaq Helsinki. www.wartsila.com

- Privacy notice

- Cookie notice

- Terms of Use

REQUEST MORE INFO

" * " indicates required fields

NORDHAVN 68 FORWARD PILOTHOUSE

Nordhavn 68 forward pilothouse.

It’s big, handsome and seaworthy.

With plenty of living room, a long list of comfort and convenience features and the range and size to cross oceans, the Nordhavn 64/68 series has proven a popular trawler size, bridging the gap between the Nordhavn 55 and the larger Nordhavn 76. Built on the same extended hull as the aft pilothouse Nordhavn 68, the new forward pilothouse version retains the same interior layout as the Nordhavn 64, but adds four feet (1.2 meters) of length to the aft cockpit, increasing the outdoor living (and playing) space to 191 square feet (17.7 square meters). An additional benefit—one that’s always appreciated— is a larger lazarette. Compared to the Nordhavn 64, the N68 forward pilothouse enjoys the advantage of a slight increase in cruising efficiency because of its longer waterline. Compared to the Nordhavn 64, the N68 forward pilothouse enjoys the advantage of a slight increase in cruising efficiency because of its longer waterline. Compared with its aft pilothouse sibling, the forward pilothouse version has a slightly larger fuel capacity at 3,230/12,226 L versus 3,136 gallons/11,871 L for the aft pilothouse version.

Living on one level

The saloon, galley, cabins and machinery spaces in the Nordhavn 68 forward pilothouse are the same size and layout as the Nordhavn 64. It’s an arrangement that some people prefer over the aft pilothouse version. “In this layout, the advantage is you get the owner’s cabin closer to the middle of the boat,” points out Jeff Leishman, the Nordhavn 68’s designer and chief designer for Pacific Asian Enterprises. A cabin closer to the boat’s geometric center sees less motion and is therefore more comfortable at sea and at anchor. Also, since the cabin is located in a wider part of the boat, it’s roomier. The teak or cherry joinery used in the master and guest cabins, and throughout the yacht, reflects PAE’s high standards of workmanship. The head for the owner’s cabin features a tile floor, granite countertops and a teak vanity. The other big advantage the Nordhavn 68 forward pilothouse shares with the 64 is that the two guest cabins are on the same level as the living spaces—the galley and saloon. So, less time is spent climbing up and down stairs—climbing stairs can be a burden for older guests. Having the guest cabins just a few paces away from the owner’s cabin is also an advantage if a family lives on the boat and the cabins are occupied by children. The starboard cabin is equipped with bunks or twin beds and the port cabin has a queen-size bed. The guest head and shower are in the bow. Finished in teak, with granite countertops and a tile floor, it is accessible by doors in each cabin.

Saloon and galley

The roomy saloon, at 11 feet 3 inches by 17 feet (3.4 meters by 5.1 meters), retains the same space as the Nordhavn 64. To maximize living space, the saloon extends the full beam of the yacht on the port side. An 18-inch-wide (45 centimeters) walkway leading from the cockpit to the pilothouse and foredeck is on the starboard side, however a dual-walkway version can be ordered. There are two seating areas in the saloon with settees and tables, as well as a large lounge chair. Varnished teak or cherry wood paneling, premium carpeting and upholstery and soft overhead lighting make the Nordhavn 68’s saloon a relaxing place to spend time on a passage. The four 26- inch (66 centimeters) by 42-inch (106 centimeters), half-inch thick (1.2 centimeters) tempered windows afford an outstanding view of the changing scenery outside. Like all good sea boats, handholds are strategically placed throughout the living area. The 21-square-foot (1.9 square meters) galley adjacent to the saloon is fully equipped with first-rate appliances, including a Sub-Zero side-by-side refrigerator/freezer, and GE cook top and stainless steel convection wall oven. There are two additional GE freezers located in the utility room. The bull-nosed countertops are granite in the owner’s choice of colors.

Seagoing pilothouse

Up a short flight of stairs from the saloon and galley is the Nordhavn 68’s pilothouse. Though not as large as the aft pilothouse version, its location amidships, where motion is minimal, is another advantage it enjoys. The pilothouse measures a spacious 14 feet (4.2 meters) by 18 feet (5.4 meters), with a generous 6 feet 9 inches (two meters) of headroom. Paneled in varnished teak or cherry, it has a settee and table, double pilot berth where the off-watch can be close at hand during night passages or in inclement weather, and numerous cupboards, drawers, lockers and bookcases. It makes a great guest cabin when in port. Eleven half-inch thick (1.2 centimeters) tempered-glass windows offer a commanding view in all directions. The helm station features two Stidd slimline chairs, an instrument console 6 feet 8 inches (2.03 meters) wide, with plenty of room for instruments, gauges and controls, and a 30-inch (76 centimeters) destroyer wheel.