- Lines & Rigging

- Sailboat Standing Rigging

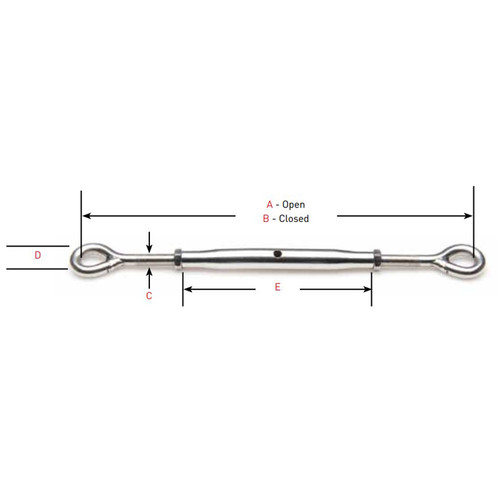

Turnbuckles

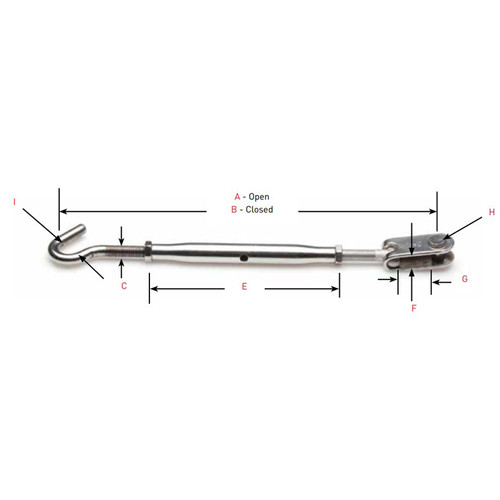

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 1/2-20

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 3/8-24

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 5/16-24

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 1/4-28

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 5/8-18

Johnson Marine Hook-to-Jaw Stainless T-316 Tubular Turnbuckle 10-32

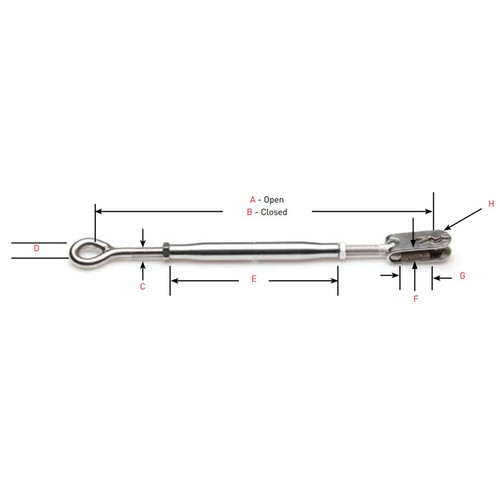

Johnson Marine LH Eye to RH Jaw T-316 Stainless Tubular Turnbuckle 5/8-18

Johnson Marine RH Eye to LH Jaw T-316 Stainless Tubular Turnbuckle 5/8-18

Johnson Marine LH Eye to RH Jaw T-316 Stainless Tubular Turnbuckle 1/2-20

Johnson Marine RH Eye to LH Jaw T-316 Stainless Tubular Turnbuckle 1/2-20

Johnson Marine LH Eye to RH Jaw T-316 Stainless Tubular Turnbuckle 3/8-24

Johnson Marine RH Eye to LH Jaw T-316 Stainless Tubular Turnbuckle 3/8-24

Johnson Marine LH Eye to RH Jaw T-316 Stainless Tubular Turnbuckle 5/16-24

Johnson Marine RH Eye to LH Jaw T-316 Stainless Tubular Turnbuckle 5/16-24

Johnson Marine LH Eye to RH Jaw T-316 Stainless Tubular Turnbuckle 1/4-28

Johnson Marine RH Eye to LH Jaw T-316 Stainless Tubular Turnbuckle 1/4-28

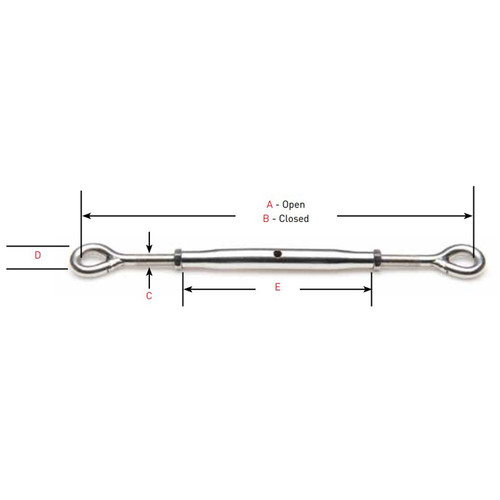

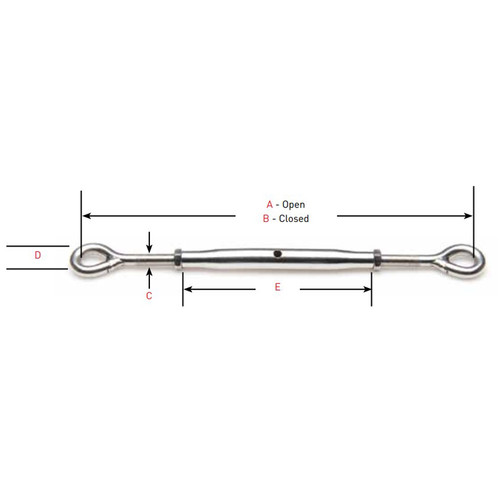

Johnson Marine Eye-to-Eye Stainless T-316 Tubular Turnbuckle 5/8-18

Johnson Marine Eye-to-Eye Stainless T-316 Tubular Turnbuckle 1/2-20

Johnson Marine Eye-to-Eye Stainless T-316 Tubular Turnbuckle 3/8-24

Johnson Marine Eye-to-Eye Stainless T-316 Tubular Turnbuckle 5/16-24

Receive News, product promotions & gifts

Your cart is empty

Use this bar to show information about your cookie policy.

Adjusting Your Turnbuckles

Ahoy, fellow cruisers! If you’re eager to keep your boat’s rig in tip-top condition, you’re in for a treat. In this easy-to-follow guide, we’ll delve into the world of turnbuckle adjustments – a vital component of maintaining your vessel’s health and performance. Although we won’t be diving into the intricacies of full rig tuning just yet, mastering turnbuckle adjustments is a fantastic step towards that path. So, get ready to learn the ropes and ensure your sailboat’s rig stays robust and ready for your next adventure.

Before we dive into the nitty-gritty, let’s ensure we’re all on the same page. A turnbuckle is a threaded device that connects various parts of your boat’s rigging system, allowing for tension adjustments. Adjusting turnbuckles is not just about fine-tuning – it’s preventative maintenance that prolongs the life of your rig.

Step 1: Cotter Pin Removal

First things first, it’s time to remove the cotter pins. These small pins secure the turnbuckles in place. Gently unbend the cotter pin’s legs, one at a time, until they’re nearly aligned. Gradually bring them together, taking care not to twist them. The right pair of pliers, preferably with a small nose, will come in handy here. A slight wiggle should align the pins, making them easy to remove. Set these pins aside safely.

Step 2: Adjusting the Turnbuckle

The terminal has flats for gripping with a wrench. Opt for a vice grip-type wrench for a secure hold. Keep the wire steady as you turn the turnbuckle – this prevents wire damage.

Knowing the direction of the threads is crucial. Typically, the upper thread is right-hand, while the lower thread is left-hand. Turn the turnbuckle in the appropriate direction – lefty-loosy for the upper thread. Count your turns. Keep an eye on the thread slopes – the right side of the right-hand thread is higher. After loosening, apply marine-grade grease generously for longevity and smoother adjustments.

Step 3: Retightening and Maintenance

Reverse the turnbuckle to tighten it back up. Counting your turns to reset the tension level. Always secure the wire to prevent any twisting. For turnbuckles with stem ball fittings, make sure they’re secured to avoid rotation. When unsure, avoid backing up the turnbuckle entirely – stick to minor adjustments. Apply fresh grease and tighten every two years for a healthy rig.

And there you have it, cruisers – a quick guide to adjusting turnbuckles on your boat. Remember, mastering this skill is the first step towards a finely-tuned rig. Regular adjustments, grease application, and proper thread handling will keep your rig in ship shape condition.

Products we use in the video:

The sealant we use for everything https://amzn.to/3n0FdRA Put on every screw and dissimilar metal https://amzn.to/40CdqVp Lubricate mast car synthetic bearings with https://amzn.to/3Na8kfF Our favorite masthead light https://amzn.to/3N5nWBj Alternate masthead light https://amzn.to/3V0fCVn Wind indicator https://amzn.to/3V1War8 Locking Crescent we love https://amzn.to/3Ao7C76 Lightning dissipater rod https://amzn.to/41Dv9gk My daily protein https://amzn.to/3oH4NeU

Leave a comment

All comments are moderated before being published

Receive the latest in marine hardware & services promotions and new releases. Subscribe and you won't miss a thing!

100% free, Unsubscribe any time!

Get In Touch

Helpful information, stay connected.

Sign up for monthly news and promotions

Affiliates & Dealers

Store location.

Salt Creek Marina 107 15th ave SE St Petersburg, Fl, 33701

- Opens in a new window.

Save to existing

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Maintenance

Tuning A Sailboat Rig

Advertisement

If your sailboat seems slower, follow our how-to on tuning your rig for optimal performance.

Photo: Bigstock

Spring is a time of prepping your boat for the coming season. While powerboaters fine-tune their engines, sailors should consider fine-tuning their rigs. Doing it yourself may seem intimidating, but it shouldn't be. Anyone reasonably handy can do it in a few hours. The reward is easier and faster sailing throughout the coming season.

Let's start with the basics for new sailors. With a few exceptions, a sailboat mast is held up by a series of stainless-steel wires. But those wires also perform several other equally important functions. When a sailboat is at rest and there is no wind blowing, the stress on these wires is very light with almost all the load downward toward the keel. However, when the boat is sailing and heeled over in a fresh breeze, more stress is placed on the wires and they have to work harder to hold the mast upright and stop it from bending.

The wires that prevent the mast from moving from side to side are called shrouds, and the ones that prevent fore and aft movement are called stays. The larger and taller the mast, the greater the load, and the number of shrouds and stays required. On a typical cruiser, say up to about 35 feet, there will generally be one forestay, one backstay, and two shrouds on each side.

To get the best performance from your boat and sails, the rigging needs to be set up correctly — often called "tuning the rig." The rig should be tuned with the boat in the water on a day with little to no wind. You'll also want to be away from wakes and other boats that can rock your boat. To start, the turnbuckles for the stays and shrouds should be hand-tight only. This is sufficient to hold up the rig but places no strain on anything — yet. Lay on your back on the boat's foredeck and sight up the front of the mast. It should be perfectly straight with no bends or kinks. Next, tighten the lower shrouds — these are the ones that do not go all the way to the top of the mast and often attach to the mast at the base of the crosstrees (the two horizontal spars at the upper ends of the topmasts).

You'll need a large screwdriver to rotate the turnbuckle, and a wrench to hold the shroud fitting and prevent it turning as you tighten. Give a couple of complete turns on either side. Have a helper release the main halyard and keep a little tension while you pull down the end that normally attaches to the mainsail until it just touches the top of the toerail adjacent to the chain plate. Have your helper cleat off the halyard, then swing the halyard over the boom and check the measurement on the other side. They should be the same. If not, adjust the turnbuckles until they the measurement is equal on port and starboard.

Adjusting and tuning a sailboat rig will often bring benefits such as easier handling and better performance.

Next do the same for the cap shrouds, these are the ones that go to the top of the mast, but note that due to the length of the shrouds, it is easy to bend the mast to either port or starboard. With the shrouds adjusted, sight up the mast one more time to ensure that it is still straight.

Next comes the fore and aft adjustment, which is made with the backstay and forestay. Masts should be plumb or lie back slightly. It should never rake forward. A good starting point is to tighten up the forestay and backstay a little over hand-tight. Use the main halyard as a plumb bob. Cleat off the halyard so the free end is just clear of the top of the boom and let it hang. If the shackle on the end of the halyard hits the mast, the mast is likely too far forward, so slacken off the forestay and tighten the backstay. Adjust a little at a time until the end of the halyard hangs free — 4 or 5 inches is a good starting point.

You'll need to install cotter pins into the turnbuckles to prevent them loosening over time, but before doing that, take the boat for a sail when the wind is blowing about 10 knots and see how everything works. With the boat on a beam reach, note the tightness of the windward shrouds. If they appear slack, they will need to be adjusted up. If the boat is hard on the tiller or wheel and tries to turn into wind, the mast has too much aft rake, so you'll want to slacken the backstay and tighten up on the forestay a little. If the bow wants to turn away from the wind, the mast is too far forward, so you'll need to move the mast back a little.

If you are at all unsure about tackling this task, play it safe and smart — seek out the services of a qualified rigger who has access to rig tension gauges and other specialized tools.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Contributing Editor, BoatUS Magazine

A marine surveyor and holder of RYA Yachtmaster Ocean certification, BoatUS Magazine contributing editor Mark Corke is one of our DIY gurus, creating easy-to-follow how-to articles and videos. Mark has built five boats himself (both power and sail), has been an experienced editor at several top boating magazines (including former associate editor of BoatUS Magazine), worked for the BBC, written four DIY books, skippered two round-the-world yachts, and holds the Guinness World Record for the fastest there-and-back crossing of the English Channel — in a kayak! He and his wife have a Grand Banks 32.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Parts of a Sailboat Rigging: A Comprehensive Guide

by Emma Sullivan | Aug 6, 2023 | Sailboat Maintenance

Short answer: Parts of a Sailboat Rigging

The sailboat rigging consists of various components essential for controlling and supporting the sails. Key parts include the mast, boom, shrouds, forestay, backstay, halyards, and sheets.

Understanding the Basics: A Comprehensive Overview of the Parts of a Sailboat Rigging

Title: Understanding the Basics: A Comprehensive Overview of the Parts of a Sailboat Rigging

Introduction: Sailboats have been a symbol of freedom and adventure for centuries. Whether you are an avid sailor or an aspiring skipper, understanding the various components that make up a sailboat rigging is essential. In this insightful guide, we will dive into the world of sailboat rigging, unraveling its intricacies while shedding light on its importance and functionality. So tighten your mainsails and let’s set sail on this knowledge-packed journey!

1. Mast: The mast is the vertical spar that supports the sails . It provides structural integrity to the entire rigging system and enables harnessing wind power effectively. Constructed from materials such as aluminum or carbon fiber, modern masts are designed to be lightweight yet robust enough to withstand varying weather conditions .

2. Standing Rigging: The standing rigging refers to all fixed parts that support the mast. This includes stays (fore, back, and jumper) which run between the masthead and various points on the hull or deck, like chainplates or tangs. Shrouds (cap shrouds, intermediate shrouds) help counteract lateral forces by providing lateral support to prevent excessive sideward movement of the mast.

3. Running Rigging: Unlike standing rigging, running rigging comprises lines that control sails’ deployment and trim dynamically during sailing maneuvers . The halyard raises or lowers a sail along its respective track within the mast groove while keeping it securely fastened in place when needed.

4. Sails: Of course, we can’t discuss sailboat rigging without mentioning sails themselves! They are like wings for your boat – converting wind energy into forward motion efficiently . Main sails typically attach through slides onto a mast track using luff cars for easy hoisting and lowering during different conditions.

5. Boom: The boom plays a crucial role in sail control , as it connects the aft end of the mainsail to the mast. By controlling the angle of the boom, sailors can adjust the shape and trim of the main sail for optimum performance against varying wind conditions.

6. Spreader: Spreader arms are horizontal poles extending from some point up the mast’s length. They serve two purposes: keeping shrouds apart to improve sail shape and reducing compressive loads on the rigging by forcing them away from each other.

7. Turnbuckles: Turnbuckles are adjustable devices used to tension standing rigging elements such as shrouds and stays. These fittings allow sailors to fine-tune rigging tensions while maximizing stability and overall performance based on prevailing weather conditions.

8. Winches: Winches are mechanical devices primarily used for easing or trimming running rigging lines under high loads. With a simple rotation, winches convert human effort into mechanical advantage, allowing efficient handling of lines for adjusting sails in different situations.

Conclusion: Understanding your sailboat rigging is not just essential for safe sailing but also for harnessing its maximum potential during every voyage. From deciphering various components like masts, standing and running rigging, booms, spreaders, turnbuckles, and winches – each element plays a crucial role in ensuring a smooth sailing experience. So next time you find yourself out on open waters, take a moment to appreciate these intricate systems that keep you powered by nothing but wind!

Step by Step Guide: How to Properly Assemble and Install the Various Parts of a Sailboat Rigging

Welcome fellow sailors and enthusiasts! Today, we are diving into the intricate world of sailboat rigging. Whether you are an experienced sailor or a newcomer to the sailing community, understanding how to properly assemble and install the various parts of a sailboat rig is essential for smooth and safe sailing. So, grab your tools and let’s get started on this step-by-step guide !

Step 1: Gather Your Tools and Materials Before embarking on this rigging journey, it’s crucial to have all your tools and materials ready. Here is a list of essentials you’ll need:

– Stainless steel wire rigging – Turnbuckles – Fittings and hardware such as clevis pins, shackles, and thimbles – Measuring tape or ruler – Wire cutters – Crimping tool or swaging machine (depending on your preference) – Electric drill (if required) – Lubricant or anti-seize compound

Make sure you have everything organized before starting. A well-prepared sailor is a successful one!

Step 2: Inspect Existing Rigging (If Applicable) If you own a used boat or are replacing old rigging, take some time to inspect the current setup. Look out for any signs of wear, frayed wires, or damaged fittings. It’s crucial to address these issues before proceeding with installation as they can compromise safety at sea.

Step 3: Measure Twice; Cut Once! Now that everything is set up let’s proceed by measuring the length needed for each piece of wire rigging carefully. Tinier inaccuracies in measurement during this step can lead to major inconveniences later.

Ensure you give yourself ample space for adjusting tension using turnbuckles. Pro-tip: It’s better to cut the wire slightly longer than needed rather than cutting it too short!

Step 4: Attach Fittings – The Devil Lies in Details Once you have measured and cut the rigging wire, let’s start attaching the fittings. This is where precision comes into play. Begin with inserting thimbles onto each end of the wires to avoid kinks or fraying. Next, connect the turnbuckles and fittings according to your sailboat’s specific rigging plan.

Step 5: Tension Matters Now that you have installed all the necessary fittings, it’s time to tension the rigging. This step requires a bit of finesse as over-tightening can damage equipment, while under-tightening can compromise performance.

Using a tension gauge, ensure that you achieve optimal tension on all parts of your sailboat’s rigging. It might take some trial and error, but finding that sweet spot is worth it!

Step 6: Inspect and Lubricate Before setting sail , always double-check everything! Look for any loose fittings or signs of wear once again. You wouldn’t want to go through these steps all over again out in the middle of nowhere!

Additionally, apply lubricant or anti-seize compound to prevent corrosion and ensure smooth operation of turnbuckles and other moving parts.

And there you have it – a professionally and properly assembled sailboat rigging! Sit back for a minute or two to appreciate your workmanship before feeling that excitement rush through as you’ll soon set sail smoothly onto those horizon-stretching waters.

Remember, practice makes perfect when it comes to mastering this skill. Over time, you’ll develop your own techniques and become a maestro at sailboat rigging assembly. Happy sailing!

Top Frequently Asked Questions about Sailboat Rigging Components Answered

Are you new to sailing or considering purchasing a sailboat? No matter your experience level, understanding the rigging components of a sailboat is crucial for safe and successful navigation on the water. In this blog post, we aim to answer some of the top frequently asked questions about sailboat rigging components. So, let’s dive in!

1. What are sailboat rigging components? Sailboat rigging components refer to the various parts and systems that help support and control the sails on a sailboat. These components include standing rigging (the fixed parts) and running rigging (lines that can be adjusted). Some common examples of rigging components are the mast, boom, shrouds, stays, halyards, sheets, and blocks.

2. What is the purpose of each rigging component? Each component serves a specific purpose in sailing . The mast supports the sails and provides leverage for controlling their shape. The boom holds down the bottom of the mainsail and allows adjustment for different points of sail . Shrouds provide lateral support to prevent excessive side-to-side movement of the mast. Stays offer fore-and-aft support to keep the mast from leaning too far forward or backward. Halyards raise and lower sails while sheets control their angle in relation to wind direction.

3. How often should I inspect my sailboat’s rigging ? Regular inspection is crucial for ensuring your safety on the water . We recommend conducting visual inspections before every sailing trip and more thorough inspections at least once a year or per manufacturer recommendations. Look out for any signs of wear, corrosion, loose fittings, or frayed lines that may indicate potential issues.

4. Can I replace my own rigging components? While minor repairs or adjustments can typically be done by boat owners with some knowledge and experience, replacing major rigging components should ideally be done by professionals who specialize in sailboat rigging services. They have the expertise and equipment necessary to properly install and tension components, ensuring your safety.

5. How long do sailboat rigging components typically last? The lifespan of rigging components depends on various factors such as usage, maintenance, and exposure to environmental conditions. Stainless steel stays can last for 10-15 years or longer with regular inspections and maintenance, while synthetic running rigging (such as ropes made from high-performance fibers) may have a shorter lifespan of 3-5 years.

6. Are there any safety tips related to sailboat rigging? Absolutely! Always wear appropriate personal protective equipment when working with or near rigging components. Take care not to overload or overstress the rig by correctly tensioning lines within manufacturer specifications . Avoid standing under or in close proximity to the mast while raising or lowering it, as it can be dangerous if it accidentally drops.

7. What are some common signs of rigging failure? Rigging failures can be catastrophic, so being able to identify potential issues is vital. Look out for visible cracks, rust, elongation, broken strands on wires, loose fittings, excessive wear on ropes, or unusual noises while sailing. Any of these signs should prompt an immediate inspection and possible replacement of affected components.

In conclusion, understanding sailboat rigging components is crucial for any sailor looking to navigate safely on the water. By familiarizing yourself with these frequently asked questions and following proper inspection and maintenance practices, you’ll enjoy a smooth sailing experience while prioritizing your safety at all times!

Exploring the Essential Components: An In-Depth Look at Key Parts of a Sailboat Rigging

Sailing is a thrilling and age-old activity that has fascinated adventurers and seafarers for centuries. At the heart of every sailing vessel lies its rigging, which is a complex system of ropes, wires, and equipment that hold the sails in place and allows for precise control over the boat’s movement. In this blog post, we will take an in-depth look at the key components of a sailboat rigging to understand their importance and how they contribute to the overall sailing experience.

Mast: The backbone of any sailboat rigging is its mast. This tall vertical structure supports the sails and provides stability to the vessel . Made from materials such as aluminum or carbon fiber, masts are designed to withstand strong winds and carry considerable loads. They come in various shapes and sizes depending on the type of boat and intended use.

Boom: Attached horizontally towards the bottom of the mast, the boom serves as a critical component in controlling the position of the mainsail – typically the largest sail on board. Acting as an extension of the mast, it allows for adjustments in sail trim by pivoting up or down.

Shrouds: These sturdy wire cables are attached to either side of the mast at multiple levels, forming a crucial part of sailboat rigging’s structural integrity. Shrouds keep the mast upright by counteracting lateral forces created by wind pressure on sails . Adjustable tensioning systems enable sailors to fine-tune shroud tension according to prevailing conditions.

Stay: Similar to shrouds but located further forward on most boats, stays provide additional support for maintaining mast stability. Fore-stay runs from top-to-bow while back-stays run from top-to-aft; together they prevent excessive forward or aft bending movements during intense wind pressures.

Turnbuckles: Within sailboat rigging systems lie turnbuckles – mechanical devices used for adjusting tension in wires or ropes like shrouds or stays. These clever devices simplify the task of tightening or loosening rigging components, enabling sailors to optimize sail shape and boat performance with ease.

Halyards: Essential for hoisting sails up and down, halyards are ropes used to control the vertical movement of the sails . They are typically operated through winches, which increase mechanical advantage and make raising and lowering large sails manageable.

Blocks: Also known as pulleys, these simple yet crucial devices help redirect the path of ropes within a sailboat rigging system. Blocks increase mechanical advantage by changing the direction of applied force, making it easier for sailors to control different aspects such as sail trim or adjusting tension.

Running Rigging vs Standing Rigging: Sailboat rigging can be classified into two main categories – running rigging and standing rigging. Running rigging refers to all movable lines and ropes that control sail position, while standing rigging encompasses all stationary components that give structure to the mast. Both elements work in harmony to ensure efficient maneuverability and safety at sea .

Understanding these key components within a sailboat’s rigging is essential for any aspiring sailor or seasoned mariner alike. It not only allows them to appreciate how these intricately designed systems function together but also helps enhance their sailing skills by leveraging each component’s unique role.

So next time you set foot on a sailboat or watch one glide gracefully across the water, take a moment to admire the finely tuned rigging – a mesmerizing web of interconnected parts that enable humans to harness the power of wind and embark on unforgettable nautical adventures.

The Crucial Role of Each Part: Unveiling the Functionality and Importance of Sailboat Rigging Components

Sailboat rigging components may seem simple and insignificant at first glance, but anyone who has sailed knows just how crucial each part is to the overall functionality and performance of a sailboat. From the mast to the shrouds, every component plays a vital role in ensuring safe navigation, efficient sailing, and maximum performance on the water.

One of the most essential parts of any sailboat rigging system is the mast. Serving as the backbone of the entire structure, the mast provides vertical stability and supports various sails that catch the wind . The mast’s height and shape significantly impact a boat’s performance, affecting not only its speed but also its ability to handle different wind conditions. A sturdy mast ensures that forces are properly distributed throughout the rigging system, preventing excessive strain or potential failure.

Connected to both sides of the mast are what are known as shrouds. These cables or wires act as primary support structures for restraining lateral movement and maintaining balance in heavy winds. Shrouds come in different sizes and tensions depending on factors such as sail size and boat length. Proper tensioning of shrouds is crucial for maintaining structural integrity and minimizing flexing under intense force.

Another integral part is the forestay – a cable or wire running from near or at the top of the mast down to the bow area of a sailboat . The forestay supports forward strength and controls stay sag- an essential factor for optimizing aerodynamics by shaping how sails interact with wind. It helps maintain proper sail geometry while limiting unnecessary heel (leaning) during maneuvers or gusts.

The backstay is another component critical for stability and control. Running from either side of the stern up to near or at the top of the mast, it helps counterbalance fore-aft bending forces created by wind pressure against a boat’s sails pushing it forward. By adjusting backstay tension, sailors can fine-tune their boat’s responsiveness to changes in wind speed or balance.

The boom, a horizontal spar attached to the mast, plays a crucial role in controlling the angle and shape of the mainsail. It acts as a pivot point for adjusting sail trim, allowing sailors to maximize lift and minimize drag based on wind conditions. With its connection to the gooseneck at the foot of the mast, it enables easy raising and lowering of the mainsail for quick adjustments or docking maneuvers .

Moreover, various blocks and pulleys are scattered throughout a sailboat’s rigging system playing essential roles in creating mechanical advantages. These components reduce friction and redirect forces generated by sails and lines during sailing operations, making it easier for sailors to handle heavy loads while preserving their energy. Choosing high-quality blocks with low-friction bearings is crucial for efficient sail handling while maintaining control.

Understanding how each part functions individually is significant; but more importantly, appreciating how they work in harmony is where true seamanship resides. Rigging components must be designed and maintained carefully to ensure safety, performance, and optimal functionality on any sailing adventure.

In conclusion, sailboat rigging components may appear simple to some extent but hold tremendous importance in enhancing a boat’s capabilities on water. From providing vertical stability with masts and dampening lateral movement with shrouds to shaping sails’ interaction with wind using forestays and backstays – every component has a crucial role to play. Understanding how these parts function individually and collectively helps sailors navigate safely while maximizing performance out on the open sea

Troubleshooting Tips: Common Issues and Solutions related to different parts of a sailboat rigging

Introduction: The rigging of a sailboat is an essential component that allows for safe navigation and optimal performance on the water. However, like any mechanical system, it can experience issues from time to time. In this blog post, we will provide detailed professional troubleshooting tips for common problems related to various parts of a sailboat rigging. Whether you’re an experienced sailor or just starting out, these solutions will help keep your rigging in top shape and ensure smooth sailing on every adventure.

1. Mast and Standing Rigging: One common issue sailors face is the presence of squeaking noises coming from the mast or standing rigging while underway. This can be quite bothersome and distracting during a peaceful sail. To resolve this problem, start by checking the connections between different components of the rigging and tighten any loose fittings appropriately. Additionally, using lubricants specifically designed for marine environments can significantly reduce friction between movable parts, eliminating annoying creaks and groans as you ride the waves.

2. Shrouds and Forestay: Another issue frequently encountered involves misaligned shrouds or forestay tension that affects the overall stability of the mast. If you notice your mast leaning slightly to one side or backward, it’s likely due to incorrectly adjusted shrouds or an improperly tensioned forestay. To rectify this, use a tension gauge to ensure consistent tension across all shrouds while avoiding excessive strain on either side of the mast base. By maintaining proper alignment and equal tension distribution, your rigging will provide maximum support when experiencing strong winds or rough conditions.

3. Running Rigging (Lines): Running rigging encompasses all lines used for controlling sails such as halyards, sheets, and control lines – crucial elements for proper sail handling. A typical problem associated with running rigging is line chafing caused by repeated friction against sharp edges or abrasive surfaces onboard. Inspect your lines regularly for signs of wear, paying close attention to areas exposed to constant rubbing. To prevent chafing, secure protective coverings or install specialized guards where necessary. Regularly washing and lubricating your lines will also extend their lifespan and ensure smooth operation.

4. Block and Tackle Systems: Block and tackle systems play a vital role in distributing loads and facilitating the movement of sails, particularly in larger sailboats. A common issue arises when blocks become jammed or fail to rotate freely due to debris buildup or lack of proper maintenance. To address this problem, inspect all blocks systematically, disassembling them if required, and clean out any accumulated dirt or salt crystals thoroughly. After cleaning, applying a liberal amount of marine-grade grease will promote smooth rotation and reduce the likelihood of future blockages.

Conclusion: Effective troubleshooting is essential for maintaining a sailboat rigging system that performs optimally and ensures a safe experience on the water. By following these detailed professional tips, you can address common issues associated with different parts of your sailboat rigging promptly and efficiently. Remember to conduct regular inspections, prioritize preventive maintenance, and seek professional assistance whenever needed. With a well-maintained rigging system at your disposal, you can embark on each sailing journey confidently, knowing that you’re prepared to overcome any challenges that may arise along the way.

Recent Posts

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: d860ee29-60f7-11ef-95ab-6fe264dd7ffb

Powered by PerimeterX , Inc.

Sailboat Rigging: A Guide to Achieve Smooth Sailing Bliss

Understanding sailboat rigging.

Sailboat rigging is the process of setting up the sails, ropes, and associated components of a sailboat to enable it to harness the power of the wind and navigate the waters efficiently. It is a crucial aspect of sailing that directly impacts the performance, safety, and overall experience on the water.

Proper sailboat rigging involves a combination of knowledge, skill, and attention to detail. Each component plays a specific role and must be correctly installed, adjusted, and maintained to ensure optimal performance. Understanding the fundamentals of sailboat rigging is essential for both seasoned sailors and beginners alike.

The Importance of Proper Sailboat Rigging

Proper sailboat rigging is essential for several reasons. Firstly, it directly affects the performance of your sailboat. Well-rigged sails and ropes allow you to harness the wind effectively, resulting in better speed, maneuverability, and control. On the other hand, poorly rigged sails can lead to reduced performance and frustrating sailing experiences.

Secondly, sailboat rigging is crucial for safety. A well-rigged sailboat ensures that the mast, rigging components, and sails are secure and can withstand the forces of wind and waves. It minimizes the risk of equipment failure, such as broken masts or snapped rigging, which can lead to accidents or stranded situations on the water.

Lastly, proper sailboat rigging enhances the overall enjoyment of sailing. When your rigging is set up correctly, you can focus on the beauty of the sea, the thrill of the wind, and the joy of gliding through the water. It allows you to fully immerse yourself in the experience and achieve a state of sailing bliss.

Types of Sailboat Rigging Systems

Sailboat rigging systems can vary depending on the type of sailboat and its intended use. The two main types of rigging systems are the masthead rig and the fractional rig.

The masthead rig is a traditional rigging configuration where the mast extends to the top of the sailboat, and the forestay is attached near the masthead. This rigging system is commonly found on cruising sailboats and provides excellent downwind performance and stability.

On the other hand, the fractional rig is a more modern design where the forestay is attached at a point below the masthead, typically around two-thirds of the way up the mast. This configuration is often used in racing sailboats as it allows for better upwind performance and increased maneuverability.

Understanding the different rigging systems is essential as it influences the setup and tuning of the sailboat rigging. Each system requires specific adjustments and considerations to achieve optimal performance.

Essential Components of Sailboat Rigging

Sailboat rigging consists of several essential components that work together to support the mast, control the shape of the sails, and enable efficient sail handling. These components include the mast, shrouds, stays, and halyards.

The mast is the vertical structure that supports the sails and rigging. It is typically made of aluminum or carbon fiber and must be strong, lightweight, and properly secured to the sailboat. The mast is connected to the hull through a step at the base, which distributes the loads from the rigging throughout the boat.

Shrouds and stays are the primary supporting elements that hold the mast in place and provide lateral and fore-aft stability. Shrouds are attached to the mast at various points and extend out to the sides of the sailboat, while stays run from the mast to the bow or stern of the boat. These components are typically made of stainless steel wire or synthetic fibers and must be tensioned correctly to maintain the integrity of the rig.

Halyards are ropes or wires used to raise and lower the sails. They run from the masthead to the sail and allow for the adjustment of sail shape and size. Proper halyard tension is crucial for controlling the shape of the sails and optimizing their performance in different wind conditions.

Each of these components plays a vital role in sailboat rigging, and understanding their functions and proper installation is key to achieving smooth sailing.

Inspecting and Maintaining Sailboat Rigging

Regular inspection and maintenance of sailboat rigging are essential to ensure its longevity, reliability, and safety. Before setting sail, it is crucial to conduct a thorough visual inspection of all rigging components.

Start by checking the mast for any signs of damage, such as cracks, corrosion, or loose fittings. Inspect the shrouds and stays for any broken strands, kinks, or signs of wear. Pay close attention to the connections between the rigging components and the mast, ensuring they are secure and free from any potential issues.

Next, inspect the halyards for fraying, excessive wear, or damage. Check the blocks, cleats, and winches associated with the halyards to ensure they are functioning properly and are appropriately lubricated.

Additionally, check the tension of the rigging by gently pushing on the shrouds and stays. They should have a slight amount of tension, but not be overly loose or overly tight. If any adjustments are needed, refer to the sailboat’s rigging guide or consult with a professional rigger.

Regular maintenance tasks for sailboat rigging include cleaning, lubricating, and replacing worn-out components. Cleaning the rigging with fresh water and mild soap helps remove salt and dirt buildup, preventing corrosion and extending the lifespan of the rigging. Lubricating moving parts, such as blocks and turnbuckles, with appropriate marine-grade lubricants helps ensure smooth operation and prevents rust.

It is important to note that if any significant damage or wear is detected during inspection, it is best to consult with a professional rigger for further assessment and repair.

Common Sailboat Rigging Problems and How to Troubleshoot Them

Despite careful inspection and maintenance, sailboat rigging problems can still occur. Understanding common issues and their troubleshooting techniques is essential for every sailor.

One common problem is rigging stretch, which can lead to reduced performance and compromised safety. Rigging stretch occurs when the shrouds and stays elongate over time, causing the mast to lose its proper shape and tension. To address this issue, adjust the rigging tension using the turnbuckles or tensioning devices provided. Refer to the sailboat’s rigging guide for specific instructions on proper tensioning.

Another common problem is rigging fatigue, especially in older sailboats or those exposed to harsh conditions. Rigging fatigue is characterized by broken strands, kinks, or signs of wear. If fatigue is detected, it is crucial to replace the affected rigging components promptly to avoid potential equipment failure. Consult with a professional rigger to ensure proper replacement and rigging setup.

Improper sail trim is another issue that can affect the performance of your sailboat. When the sails are not trimmed correctly, they can become overpowered or lose their shape, resulting in reduced speed and control. Experiment with different sail trim settings, such as halyard tension, sheet tension, and traveler position, to achieve the optimal sail shape for different wind conditions. Practice and experience will help you develop a keen eye for proper sail trim.

Upgrading and Optimizing Sailboat Rigging

Upgrading and optimizing your sailboat rigging can significantly improve performance, safety, and overall sailing experience. There are several areas where upgrades can be considered, depending on your sailboat’s design and intended use.

One common upgrade is replacing wire rigging with synthetic rigging, such as Dyneema or Spectra. Synthetic rigging offers several advantages, including reduced weight, increased strength, and lower maintenance requirements. However, it is crucial to consult with a professional rigger to ensure proper installation and tuning of synthetic rigging.

Another upgrade option is replacing older blocks and pulleys with modern, low-friction alternatives. High-quality blocks with ball bearings or roller bearings can significantly reduce friction and make sail handling smoother and more efficient. Upgrading winches and cleats to larger or more powerful models can also enhance control and ease of use.

Additionally, optimizing your sailboat rigging for specific sailing conditions can improve performance. This may involve adjusting the rig tension, changing the position of the mast rake, or experimenting with different sail combinations. Consulting with experienced sailors or professional riggers can provide valuable insights and recommendations for optimizing your rigging setup.

Hiring a Professional Rigger for Sailboat Rigging

While basic sailboat rigging tasks can be performed by experienced sailors, complex rigging projects or major upgrades are best left to professional riggers. Hiring a professional rigger ensures that the rigging is installed, adjusted, and maintained correctly, minimizing the risk of equipment failure and maximizing the performance of your sailboat.

Professional riggers have the knowledge, expertise, and specialized tools to handle various rigging projects, from simple replacements to complete rig overhauls. They can assess the condition of your current rigging, recommend necessary upgrades or repairs, and provide valuable advice on rig tuning and optimization.

When hiring a professional rigger, it is essential to do thorough research and choose a reputable and experienced individual or company. Seek recommendations from fellow sailors, check online reviews, and inquire about their certifications and qualifications. A reliable professional rigger will work closely with you to understand your sailboat’s specific requirements and ensure that the rigging is tailored to your needs.

Safety Considerations for Sailboat Rigging

Safety should always be a top priority when it comes to sailboat rigging. Here are some important safety considerations to keep in mind:

- Always wear appropriate personal protective equipment, such as a life jacket and harness, when working on the sailboat rigging, especially at heights or in challenging conditions.

- Use proper lifting techniques and equipment when handling heavy rigging components to prevent injuries.

- Be mindful of your surroundings and the potential hazards associated with sailboat rigging, such as moving parts, sharp edges, or overhead obstructions.

- Regularly inspect and maintain safety equipment, such as lifelines and jacklines, to ensure they are in good condition and properly secured.

- Follow manufacturer guidelines and recommended practices for rigging installation, adjustment, and maintenance.

- Stay updated on current safety standards and regulations related to sailboat rigging.

By prioritizing safety and adhering to these considerations, you can enjoy smooth sailing adventures with peace of mind.

Conclusion: Enjoying Smooth Sailing with Well-Maintained Rigging

Mastering the art of sailboat rigging opens up a world of endless possibilities and pure sailing bliss. By understanding the different types of rigging systems, essential components, and proper maintenance techniques, you can achieve optimal performance, safety, and enjoyment on the water.

Regular inspection, maintenance, and troubleshooting of sailboat rigging are essential to ensure its longevity and reliability. Upgrading and optimizing your rigging can further enhance your sailing experience and unlock new levels of performance.

While basic rigging tasks can be performed by sailors, complex projects or major upgrades are best left to professional riggers. Hiring a reputable and experienced rigger ensures that your rigging is expertly installed, adjusted, and maintained.

Remember to prioritize safety at all times and follow recommended practices to minimize risks associated with sailboat rigging.

So, set sail, embrace the wind, and experience the bliss of smooth sailing with well-maintained sailboat rigging. May your adventures on the water be filled with joy, excitement, and the sheer beauty of the sea.

- standing rigging

- rope and line

- cams, cleats and clutches

- head sail gear

- roller furling

- main sail control

- mast hardware

- eye straps and pad eyes

- fairleads and bulls eyes

- anchor and docking

- miscellaneous hardware

- Alexander Roberts

- My Wishlist

turnbuckles

- Customer Service

- Order Tracking

- Your Account

- Store Policies & Info

- Privacy Policy

- Helpful Links

- Payment Methods

Shopping Cart: 0 Items

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Sailing Eurybia

Two Humans and a Dog sail Mexico on a Sea Maid Ketch

Rigging Your Cruising Sailboat Yourself

April 14, 2022 1 Comment

Aside from holes below the waterline of your hull, losing a mast is about the scariest thing that can happen to your boat. Did you see the dis-masting in the movie Master and Commander? This is the stuff of nightmares for a cruising sailor. Since the general advice is to replace wire rigging every ten years most of us have to confront this task at least once during our sailing lives. And even among sailors who take on many repair tasks on their boats, replacing the standing rigging is something many sailors would not consider doing themselves. We are now on our second re-rig (different boats) and can say that, with several caveats, it is a very doable task for most handy folks. In this article I walk you through what we do so you can decide if re-rigging is a DIY task or not for you.

In general, any situation requiring a redesign, whether total or partial, we feel should be done only after consulting with professionals. This includes any situations involving change of materials or geometry. For example if we were going from rod to wire rigging, or from wire to HMPE (High Modulus Polyethylene e.g. dyneema), we would consult professionals. Likewise if we were replacing a mast or spreaders we would involve professionals because these situations create different loads on the rigging and therefore may require resizing the wire or attachment points. And of course if you have any reason to feel that the current rig is not adequate you do not want to repeat those mistakes in the new rig and you will also need a redesign. Get a professional involved in these cases.

You also need a professional shop if you want swaged rigging. But if you want mechanical fittings you can do it yourself. If you currently have swaged fittings, as we did on both the boats we have rerigged, then you will need to research and buy some different terminals, but the design can remain the same. We will talk about what we used below.

However if you feel that your current rig is adequate, just aging, you may wonder what is involved in doing it yourself. Besides saving money on someone else’s labor, you would have the satisfaction of know how your rigging is put together.

Your boat may be quite different from ours, but here is our experience with re-rigging a boat with swaged fittings and converting to Sta-Lok mechanical fittings.

Eurybia is a ketch with one unusual feature – a solid triatic. A triatic is the stay connecting two masts. Usually this is a wire stay, but our boat was designed and rigged with a solid bar running from the mizzen mast to the split backstay of the mast. The solid triatic resists both pushing and pulling so that backstays or swept spreaders are not required on the mizzen. I will not talk much about this feature as most people do not have to worry about this. Everything else about our re-rigging applies to other Marconi / Bermuda rigged boats such as sloops, cutters, ketches and yawls since we are just talking about the wires and the attachments.

Rigging Nomenclature

The Cap Shroud goes from the top of the mast to each spreader and then to the deck beside the mast.

The Aft Lower Shroud goes from the mast just under the lowest spreader to the deck aft of the mast. The Forward Lower Shroud goes from the mast just under the lowest spreader to the deck forward of the mast.

If you have more than one spreader each additional spreader will have its own shrouds that go from the mast just below the spreader above it, through the spreader end, to the deck beside the mast. These can be called the Upper Shroud or Intermediate Shroud .

The Forestay goes from the top of the mast to the bow of the boat – on Eurybia this is part of the jib furler and is not part of this re-rig

The Backstay goes from the top of the mast to the stern of the boat. On Eurybia there is an upper backstay about 20′ long, then a junction where two lower backstays proceed to a point on either side of the boat just aft of the mizzen mast. This junction is also where the solid triatic bar connects to the top of the mizzen mast.

Running backstays go from just under the top spreader to the deck aft of the mast ending with a rope tackle so it can be easily loosened or tightened.

Continuous / Discontinuous . Most boats have shrouds that are a continuous piece of wire as they go past the spreader, others are discontinuous at the spreader requiring additional attachments points here. Eurybia has continuous shrouds and our last boat had discontinuous. It is possible to convert a discontinuous rig to a continuous one but you will have some redesign of the spreader ends.

Eurybia’s main mast has two spreaders and therefore has port and starboard cap shrouds, port and starboard intermediate shrouds, port and starboard lower aft shrouds, and port and starboard lower forward shrouds for a total of eight. There is also a forestay as part of the furling jib and a split backstay. Finally there is a running backstay on either side. The mizzen mast has one spreader and therefore has two cap shrouds, two lower aft, and two lower forward shrouds. There is no backstay or running backstay on the mizzen. The equivalent of a mizzen forestay, the triatic connects the backstay of the main mast.

Rigging Tools And Supplies

Caliper for measuring shroud thickness. Eurybia has shrouds of 1/4″, 5/16″, and 3/8″. For an inexpensive digital caliper see Amazon . Harbor Freight also has inexpensive digital calipers.

Hacksaw for cutting wire. We recommend that you do this manually rather than using an angle grinder or other electrical saw because the speed of the electric saws can affect the strands, even melting them a bit so they are difficult to untangle.

Sawing jig for holding wire and preventing the strands from separating. (see image)

Vise and work table for cutting wire and installing terminals. The vise should have aluminum or brass jaws so as not to mar the stainless terminals.

50-100′ Measuring tape. We used a long cloth tape on a roller such as is used for landscaping. For our 45 foot boat the longest shrouds were 50′ but yours may be even longer.

6′-25′ Measuring tape for measuring the hardware.

A place to lay out and measure the wire . Here in Puerto Penasco, Mexico we are working in a very dusty yard and are using the mast (lying horizontally at working height on sawhorses) as our “table” for laying out wire. First we taped the zero end of the landscape tape to the top of the mast and taped it down every few feet to the foot of the mast. Eurybia is keel-stepped and the mast is longer than the longest shroud – if you have full backstays or are deck-stepped you might have to add another horizontal surface to have enough room to measure the longest wires. The mast track made an ideal place for capturing the wire rope while we measured and cut it.

Notebooks and pens . There are a lot of numbers to capture!

Painters tape and sharpies for labeling the wires.

Velcro Cable Straps or Electrical tape . This is to secure the long lengths of wire in loops so it is easier to handle. We didn’t have cable straps so we used ALOT of tape during the process.

The old shrouds for measuring from. Before unstepping the mast we marked with painters tape the location of the turnbuckles on each shroud so we would know the ideal length of each. While unstepping the mast these turnbuckles will be loosened but the tape allowed us to return to the design length. It is also essential to label each shroud with its position (cap shroud port, lower port fwd, etc) as well as its diameter (3/8″).

The new wire in all the appropriate diameters to match the old shrouds. I think all modern wire rope rigged sailboats use 1×19 stainless wire. Wire can be 304 stainless, or 316 which is a little less strong but more resistant to corrosion. Diameter of the wire MUST match the old wire but the 304 or 316 does not matter. Your preference.

Terminal ends for both ends of each shroud. You will need new mechanical terminal ends for a swaged rig. If your rig currently has mechanical ends, you can reuse these at least once and just replace the cones. If replacing the cones get some extras. Sta-Lok and Hayn still make these parts. Hayn is probably the best and most expensive. If your boat currently has Norseman fittings you will have to decide whether to continue with those parts as Norseman is no longer in business. You can still get the cones from Tylaska if you happen to already have a Norseman system.

We chose Sta-Lok.

Wrench for putting the terminal end on and the vise to hold the terminal eye end while turning the cone end of the terminal. We used a 12″ crescent wrench.

Sta-Lok System

To replace your current eyes at top and bottom of the shrouds with Sta-Lok fittings, go to the Sta-Lok website .

We used Sta-Lok eyes at the top of each shroud. We replaced the swaged toggle on the end of each turnbuckle with a new toggle. Then the pin on these new toggles inserts through the Sta-Lok eye. (see image below)

Basic Steps for Rigging

Make wire cutting jig.

Cut a square piece of wood about 3-4″ on each side. Hardwood would be best but we used epoxied plywood and it was adequate. For each diameter of rigging wire your boat requires drill a hole that size near the corner of the block. Write the diameter near the hole with sharpie. You will insert the wire through this hole in order to hold it for cutting and to prevent the strands from separating.

Using a skillsaw cut a slice in the middle of the block starting at the corner and continuing through the hole you just made. This is where your saw blade will go while cutting the wire.

Repeat at each corner of the block for the sizes of wire you require. (Eurybia used 1/4″ 5/16″, and 3/8″).

Before Unstepping the Mast: Document Existing Rig

Mark Turnbuckles. Assuming your existing rig is currently optimally tuned or close, use painter’s tape to mark the location of the turnbuckles. This will help you to return close to a tuned length.

Label shrouds and chainplates. Label every wire both at deck where it connects and the wire itself. Remember to indicate port or starboard, which mast, which shroud – so “Mizzen Cap Port” or “Main Upper Port” or “Main Lower Port Forward” etc. For the deck markings “Cap”, “Lower Fwd”, “Lower Aft” etc is sufficient.

Measure Old Shroud Assemblies

Unstep the mast.

If you are in a dirty yard like we currently are, using the mast as a place to lay out the wire is far preferable to laying the clean new wire in the dirt. Place the main mast with track facing up on horses at working height (if you wish to use the mast to measure and lay out the wires).

Tape a landscape measuring tape the entire length of the mast track. Secure it every 5 or 10′ down the length. See image.

Remove all the old shrouds. Return turnbuckles to the tension marked by the painter’s tape.

Measure each old shroud from center of the top eye to center of the bottom eye and enter the length and diameter into your notebook. This is the “assembly” length and is the total finished length.

Measure and Cut New Rigging

Gather the top and bottom terminals (including turnbuckles etc) that you will use for the this particular shroud, either removing them from the old rig if you are reusing, or the new hardware if you are replacing it. You need two numbers – one is the length of top hardware from the center of the eye to where the wire will start when inserted in the terminal – write this down. Then the second number is from the eye of the bottom hardware – including turnbuckles – up to where the wire will end when assembled. Add these two numbers together – top and bottom – this is the “hardware length” of the new rig. Subtract “Hardware length” from the “assembly length” to get “Cut Length” – the actual length of wire that you need. Write this down.

After you finish documenting the lengths and cut lengths of all the shrouds, you are ready to start cutting (and labeling!) wire. It is simplest if you do all wires of one diameter before moving to new wire.

Measure and Cut. Lay the new wire on the mast track and slide the jig you made onto the wire. Measure the cut length carefully and mark the wire with sharpie. You can cut it in place, but it would be best to move the wire to a workbench with a vise. Clamp the jig in the vise and slide the wire until the mark is centered in the block. Using a hacksaw cut the wire. Slide the block past the cut, ready for the next cut.

Tape both ends of the cut shroud so the strands don’t unravel.

Label the wire (“Lower Port Aft” or whatever). Roll, tape, and set aside.

Repeat for all the wires of this diameter and then repeat for each diameter wire.

Install Terminals

Use the instructions for the type of terminal you are using. We used Sta-Lok terminals and these instructions . In most instances you will place a terminal eye at the top and the terminal eye connected to a turnbuckle at the bottom of the wire. Although many people put 5200 (NOT recommended) or Silicon sealant into the terminals before inserting the wires, Sta-Lok doesn’t actually recommend this. We did not use Silicon this time.

We spent approximately 2-3 days to cut the wires for our two masts and apply the terminals. The wire and terminals we bought at Fisheries Supply. Even including the extensive measuring and record-keeping this is straight-forward work that most people could handle.

I think I will measure in centimeters next time. Less risk of arithmetic and recording errors!

I would love to hear from any of you about your own re-rigging experience or questions you have about doing this yourself.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

This site uses Akismet to reduce spam. Learn how your comment data is processed .

As the other half of the described rerig there are a few things I would do differently. I would scrutinize the existing rig more closely, top and bottom, of each shroud and stay. I assumed that the pin sizes would be the same on both ends of each piece of rigging which turned out not to be the case on several. I would take far more photos of each tang and it’s attendant connections than I think necessary which would simplify reassembly. I would use StaLok studs at the turnbuckle end of each shroud and stay rather that toggles. It … Read more »

Stay in touch - sign up for our newsletter for occasional news from Eurybia and her crew.

Your Boat Name:

Email address:

- Privacy Policy

“Live in the sunshine, Swim the sea, Drink the wild air” --Emerson

About This Site

SailingEurybia is a WordPress site. The theme is a version of the Genesis Sample Theme developed by Eurybia-Marie . ©2018

FREE SHIPPING ON ALL ORDERS OF $150, UNDER 50LBS

- Shop Products

- Order Status

- Shipping Return

- Request Quote

- Arborist Fliplines

- Arborist Halyard

- Arborist Lanyards

- Arborist Rope

- Arborist Slings

- Gripple Wire Hangers

- Steel Wire Rope

- Fiddle Block

- Foot Hardware

Turnbuckles

- Positioning Lanyards

- Tool Drop Prevention

- Rescue Rope

- Double Braid

- Rigging & Marine

RIGGING SUPPLY YOU CAN DEPEND ON

US Rigging Carries Turnbuckle Wire Tensioners & Cable Tensioners

If you are looking for a turnbuckle you have come to the right place. Our turnbuckles are tough and designed for superior cable termination applications. US Rigging offers a carefully selected variety of Cable Tensioners with various end configurations, including Eye & Eye tensioners, Hook & Eye tensioners, and Jaw & Jaw tensioners. Both standard Stainless Steel Turnbuckles and Galvanized Stainless Steel Turnbuckles are super tough and excellent for outdoor applications.

What Are Turnbuckles Used For?

Turnbuckles may be referred to as Wire Tensioners, Cable Tensioners, or Cable Tighteners. These pieces of hardware are engineered to absorb slack and apply tension to a rigging system without twisting the cables or wires. When Turnbuckles is used in cable termination and tensioning, the Turnbuckle itself will twist rather than the cable or wire.

Turnbuckle Applications And Features:

- Applying Tension To A Rigging Setup

- Taking Up Slack In A Rigging Assembly

- Preventing Wires, Cables, And Lines From Twisting

What Are The Different Styles Of Cable Tensioners?

Turnbuckles/Cable Tensioners are classified by how they attach to assemblies at each end. Turnbuckles have two ends and can be configured with different connectors on each end. For example, a Turnbuckle that has a Hook Connector on one end and an Eye Connector on the other end would be classified as a Hook/Eye Turnbuckle. A Jaw/Jaw Turnbuckle has a Jaw Connector on both ends of the tensioner.

US Rigging Offers 3 Styles Of Turnbuckles:

Eye/Eye Turnbuckles These are tensioners with eyes that connect to other components of a rigging system on both sides of the hardware. Eye connectors add extra security and won’t detach from a rigging system accidentally. Because of this added security, they can be difficult to use in coordination with thimbles.

- Highly Secure Connections

- Won’t Detach From Systems Unintentionally

Jaw/Jaw Turnbuckles With jaws on each end, these turnbuckles include removable pins on each jaw. Jaws work easily with thimbles and are more secure than hook connectors. Like eyes, jaws prevent turnbuckles from becoming detached unintentionally.

- Secure Connections

- Work Easily With Thimbles

Hook/Eye Turnbuckles These turnbuckles have a hook on one end of the hardware and an eye on the opposite end. Hooks are less secure than jaws and eyes but are easily removable. These turnbuckles are ideal for applications where temporary connections are being applied and you want to remove tension more easily.

- Easily Removable

- Ideal For Temporary Connections

What Are The Benefits Of Stainless Steel Wire Tensioners?

Stainless Steel is an incredible material that is excellent for outdoor use, including applications where it may come into contact with salt water. Stainless Steel Is resistant to corrosion and rust. When you are using other components made with Stainless Steel, it is best to use Stainless Steel Turnbuckles to avoid unwanted chemical reactions.

Benefits Of Stainless Steel Turnbuckles:

- Resistant To Corrosion

- Great For Outdoor Use

- Can Come Into Contact With Saltwater

- Ideal For Use With Other Stainless Steel Components

What Are The Benefits Of Galvanized Steel Wire Tensioners?

Galvanized Steel is also great for many outdoor applications but it is not as resistant to corrosion as Stainless Steel. It is resistant to rust against freshwater, but not saltwater.

- Can Come Into Contact With Freshwater

What Turnbuckles Are Best For Heavy Loads?

Turnbuckles with longer thread diameters are the best for heavy loads. If you are working with heavy-duty loads, you will want to compare thread diameters when choosing which Cable Tensioner you are going to buy.

Who Is US Rigging?

US Rigging is a manufacturer and master distributor of climbing ropes, fall protection equipment, and industrial rigging equipment located in Santa Ana, California. This Orange County-based company is proud to provide American Made products with both safety and service in mind. US Rigging has a legacy lasting over 40 years and is known for operational excellence.

We offer a carefully selected array of turnbuckles for cable termination applications where you want to avoid twisting on your line. Browse our selection and choose between Wire Tensioners with a variety of end configurations. Our turnbuckles are available in stainless steel or galvanized steel according to your needs.

US Rigging is committed to excellence in service and providing our customers with the best rigging products on the market.

There are no products listed under this category.

FREQUENTLY ASKED QUESTIONS

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sails and Rigging

- Maintenance

- Sailing Totem

- Sailor & Galley

- Living Aboard

- Destinations

- Gear & Electronics

- Charter Resources

- Ultimate Boat Giveaway

Sailboat Rigging Tips from a Pro

- By David Bond

- Updated: May 12, 2021

Clive Strickett is a rugged guy, so it takes strong arms to winch him aloft to the masthead. But that’s exactly where you want him: eyeball to halyard sheave, looking for problems. He’s a veteran rigger with a keen eye and a background in ocean racing on the competitive Maxi circuit. On the island of Lanzarote, where I first encountered Strickett, he has a reputation for detail.

We were on the dock at Marina Lanzarote in a fresh breeze of about 20 knots. It was sunny and warm, the sort of weather you’d expect when you’re about 400 nautical miles off the coast of Morocco. These Canary Islands, of which Lanzarote is the farthest north, are a staging area for boats embarking on a trans-Atlantic crossing.

Strickett had just been lowered to the deck of a Bavaria 41 by the boat’s skipper after checking the spreaders, and was now shaking his head. Problems. There are always problems. This time it was mismatched metals. “It’s rare to find a boat that has nothing wrong with it,” he said.

Never mind the Atlantic—the first leg of the trip from the United Kingdom and Europe to the Canaries can be brutal on gear. And that’s before the 3,800-nautical-mile downwind crossing to the Caribbean. It’s wise to have a guy like Strickett check your rig before you leave. “I’ve been doing this for a few years now,” he said. “I might see a problem that the owner missed. They weren’t looking for it, or weren’t looking where they should have been.

“You never know what’s going to happen on boats. Even on new boats,” he continued. “A friend of mine had a new catamaran, a big one, with a carbon-fiber mast. One of the genoa clutches ripped right off the mast. Brand new boat, right from the factory. We had to get the OK from the factory in France to make a repair. We fixed it, and he crossed the Atlantic.”

Minor rig problems compound quickly under pressure. Strong winds funneling through these volcanic islands can mimic trade-wind sailing, but that doesn’t mean that every boat is ready for the crossing. According to Strickett, safety lies in the details, and he points out where to look for potential problems in your rig. Here’s what Strickett is looking for as he inspects a spar, from top to bottom.

Masthead: “Be sure the sheave axles are secure. Sometimes the holes elongate or even crack. And then halyards can get mixed up. One boat that came through here from Tenerife was using the wrong halyard. They were using the spinnaker halyard instead of the genoa halyard. When I went up to look at it, the sheave box was completely gone; the rivets were all loose. The holes had elongated because the halyard was at the wrong angle. They didn’t even realize it. It’s tough to see what’s happening aloft when you’re on deck.”

Working down the mast on a fractional rig, there might be additional sheave boxes fitted for internal halyards. “Make sure all the rivets are tight. Anything fitted with bolts or rivets should be double-checked.”

Spreaders: “Inspect the spreader tips; make sure they’re OK and there’s no corrosion. Whenever you get stainless steel and aluminum together, there’s corrosion. One fleet of charter boats here had put 8 mm stainless bolts into the aluminum spreaders with no protection. Now the spreaders are corroding—the holes get bigger and bigger. But not only that, the spreader was already weakened by putting big holes in it to begin with.”

Shrouds: Broken or damaged wire rigging is the most common problem. “Most cruising boats use 1-by-19 stainless wire. Inside, one strand can let go, then another. When you get up to four broken strands, the wire gets weaker and weaker, and eventually fails. If you’re underway and that happens, then you have a big problem.”

You also don’t want extra weight aloft. “Some people use Dyform, or compacted wire, which uses triangular-shaped strands around a core. If you compare a 10 mm Dyform wire to a 10 mm 1-by-19 wire, the Dyform is stronger. I once changed a 12 mm 1-by-19 wire to a 10 mm Dyform wire. It’s the same strength, but I saved some weight aloft.

“You can’t take anything for granted,” he continued. “There was a boat getting ready to head to the Mediterranean from here, which is a long slog to windward. He was all ready to go. Just as an afterthought, the owner had me look over the rig. Good thing. I found some broken wires in the forestay. The whole mast could have come down. So have a close inspection just to make sure there are no broken wires, and that the terminals don’t have any cracks in them.”

Boom: “Once again, closely inspect the rivets. Loose padeyes on the boom get looser and can easily rip right out. The same goes for the gooseneck fittings. Check every bolt, every rivet for the slightest elongation of the holes or any loose rivets. I can’t emphasize that enough. The padeye is usually secured to the boom with 5 mm Monel rivets, but those can pull loose after a sharp pull like a jibe. They can get yanked right out of the boom. Then what? As insurance, I usually remove the 5 mm rivets and replace them with 6.3 mm rivets, which are the largest you can use. If you’ve had a big jibe and the boom hits a V1 (lower shroud), it might break or bend the boom. We fix booms at our engineering shop. They’ll straighten it, put a patch on, weld it and then paint it. That makes it strong enough. New booms delivered to Lanzarote come from France, and the delivery fee alone can cost up to $3,500.”

Read More: Check your Boat’s Rig

Turnbuckles: “Some people don’t like to tape turnbuckles; they like to see what’s going on with them. Fair enough. I wouldn’t tape it all the way closed though. Just a little tape around the split pins so that they don’t grab a sail or your ankle. On one boat that I inspected, the guy had taped up the whole thing. When we untaped it, it was all manky, which means pretty disgusting. The dirt will always get in somehow. If it’s all taped up like that, you can’t oil or lubricate it. I tell people: Now and then, service your turnbuckles. Take some turns off the turnbuckle. Make sure it’s clean and then put a little Teflon gel on it, or some MolyKote grease. Then tighten it back up.

“When you haven’t done it for some years,” he added, “they seize up and you can’t undo them. Especially a small turnbuckle. They’re chrome-plated over bronze, and when you put a big spanner in there and turn it, it’ll snap. And what you don’t want is for a wire to snap when it’s under load. It’s just preventive maintenance. Do it every six months. It takes only a couple of hours.”

Headsail Furlers: “On some ProFurl furlers, there are four black bolts that go into the furler: two that hold the cage on and two that hold the plate. On the older ones, the bolts are made of titanium, and they seize into the aluminum. I don’t know how many I have had to drill out. But you have to drill them out properly. If it’s a 6 mm bolt, first you drill straight down the middle of the hole with a 3 mm drill, then with a 4 mm, then a 5 mm, then a 5.5 mm. Hopefully it will come out with the heat and friction. ‘Easy-out’ [screw extractors] don’t work. These things are seized together. Even heat doesn’t work.”

Chain Plates: “I inspected one boat with the chain plates so loose, they were actually moving. You could see where they had scratched the paint around the hull. Down below, look carefully at the chain plates. Make sure there’s no cracking in the hull, no movement on the bolts. You can see where a bolt has bent a little, or if it’s been pulled up or down. You’ll see little scratch marks on the hull or the bulkhead.”

Mast Step: “There’s a fine balance between the shrouds being too tight and too loose. There was a good-size catamaran that left here and got into some rough seas, rolling around. The shrouds were too loose, and on one roll, the mast jumped right out of its mast step. It was just for a moment, but in that moment, the mast went overboard.”

With the inspection on the Bavaria completed, as we walked up the gangway toward the marina office, I had one last question: “If something breaks underway, can a rigger or a boatyard be held responsible?”